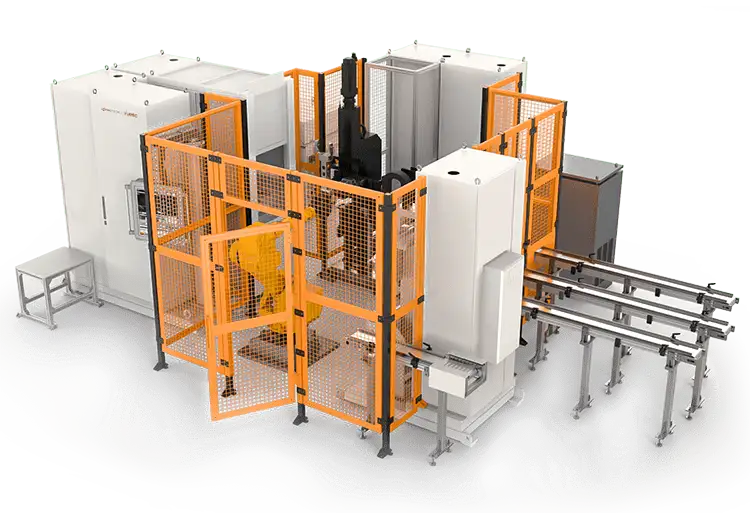

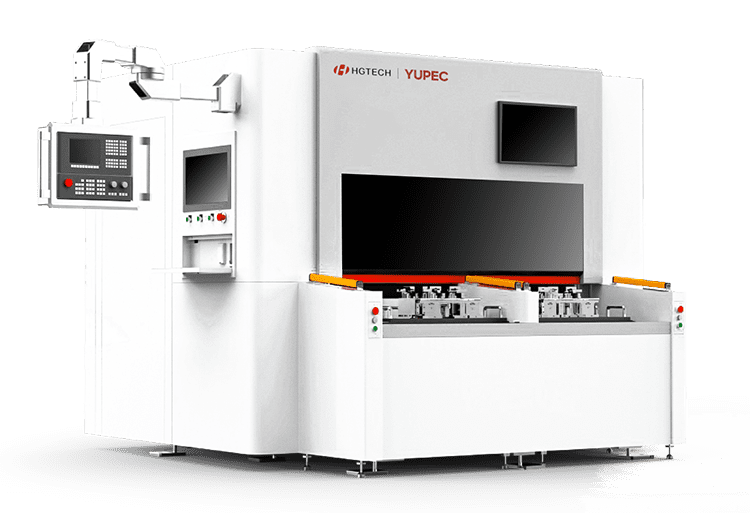

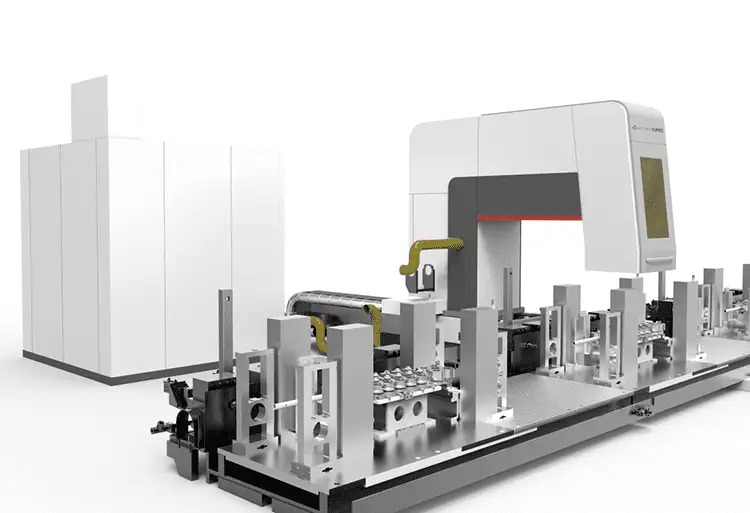

An automated laser welding machine represents a cutting-edge technology that utilizes a focused laser beam to perform welding operations with unparalleled precision and efficiency. This advanced machine employs a high-energy density laser beam to melt and fuse materials, ensuring precise and strong welds. Automated laser welding is known for its high speed, accuracy, and non-contact attributes, making it suitable for welding a variety of materials, including metals, alloys, plastics, and more.

Advantages of Automated Laser Welding Machines

Automated laser welding delivers welds with superior precision and quality compared to traditional welding methods. The focused laser beam ensures minimal heat-affected zones, resulting in welds with minimal distortion and superior strength. The automated system, integrated with advanced control mechanisms, guarantees precise and consistent welds.

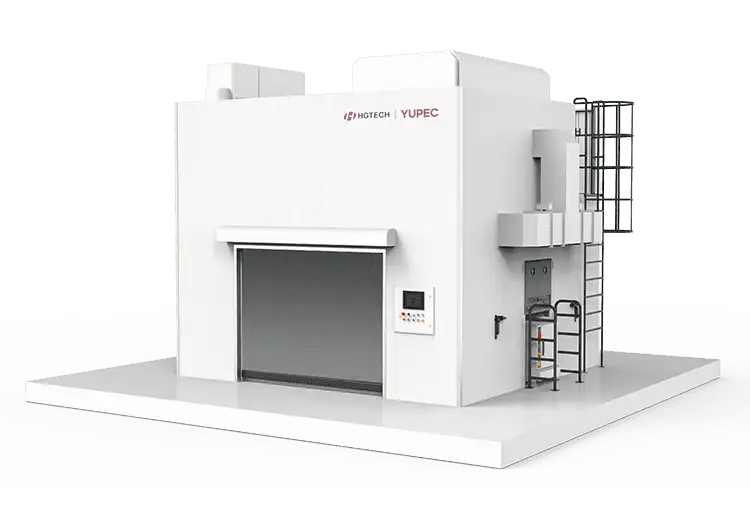

Safety is paramount in welding operations, and automated laser welding significantly reduces risks associated with traditional welding. The non-contact nature of laser welding minimizes the need for direct operator interaction with the welding process, reducing the risk of injuries. Additionally, the automated system operates within a sealed environment, ensuring the safety of personnel.

Automated laser welding offers versatility in welding different materials without the need for frequent adjustments. Whether welding metals, alloys, or plastics, the laser beam’s parameters can be fine-tuned to achieve optimal results. The automation components facilitate seamless adaptation to various materials and thicknesses.

Setup and operating times are critical factors affecting production costs. Automated laser welding significantly reduces setup times compared to traditional welding methods. The absence of time-consuming changes in electrodes or filler materials streamlines the welding process, resulting in faster production times and increased overall efficiency.

The focused laser beam used in automated welding minimizes material wastage. Narrower weld seams and reduced heat-affected zones contribute to efficient material utilization. This not only lowers material costs but also promotes environmentally sustainable manufacturing practices.

Expand to learn more

Automated Laser Welding Machines for Different Materials

Automated laser welding machines are versatile tools capable of welding a wide range of materials with precision and efficiency. The adaptability of these machines to different materials is a key factor in their widespread use across various industries. Here’s a detailed exploration of the materials commonly welded using automated laser welding machines:

Metals and Alloys

Automated laser welding is extensively used for welding metals and alloys, including stainless steel, aluminum, copper, and various steel alloys. These materials are prevalent in industries such as automotive manufacturing, aerospace, and general metal fabrication. The precision and speed of laser welding make it ideal for creating strong and reliable welds in metallic components.

Contrary to traditional welding methods, automated laser welding is suitable for joining plastic and polymer materials. It finds applications in industries such as electronics and medical device manufacturing, where precision is crucial. Common plastic materials welded include polyethylene, polypropylene, and various thermoplastics. Laser welding ensures clean and precise joins in plastic components.

Applications of Automated Laser Welding Machines

Automated laser welding machines find applications across various industries, contributing to precise and efficient welding operations. Here are key application areas and associated materials:

In the automotive industry, automated laser welding is employed for welding body components, exhaust systems, and intricate engine parts. Metals such as steel and aluminum, as well as alloys, are commonly welded using automated laser technology.

Precision is critical in electronics manufacturing, and automated laser welding is used for welding components on circuit boards and semiconductor devices. Materials such as silicon, ceramics, and metals are welded with utmost precision.

Aerospace Industry

Automated laser welding plays a pivotal role in aerospace manufacturing for welding high-strength metal alloys and titanium components used in aircraft and spacecraft. The precision and reliability of laser welding are crucial for ensuring the structural integrity of aerospace parts.

In the medical industry, automated laser welding is essential for producing precise welds in the manufacturing of medical instruments, implants, and components. Materials such as stainless steel and titanium are commonly welded in medical device manufacturing.

General Manufacturing and Construction

Automated laser welding finds applications in general manufacturing and construction for welding both metal and non-metal materials. It is used to create strong and precise welds in structural and decorative elements.

In conclusion, automated laser welding machines represent a technological leap in the field of welding, providing industries with a reliable, precise, and efficient solution for various welding applications. The adaptability of these machines to different materials and their automated features make them indispensable in modern manufacturing processes.

Send us a message

Don’t hesitate to ask, we usually reply in 24 hours or less!

Contact Information

Yupec Laser Germany GmbH

Itterpark 2, 40724 Hilden, Germany

- +49 2103 9674 492 / +49 2103 9676 682

Company Details

Yupec Laser Germany GmbH

Amtsgericht Jena, HRB 519333

Ust-Id~Nr. DE3552294798