Watch & Jewelry Industry

Currently, the watches and jewelry industry are in a new era integrating traditional craftsmanship with modern technology. While preserving traditional craftsmanship, the industry is gradually introducing intelligent manufacturing technology to enhance efficiency and precision. Specifically, laser technology is increasingly applied in this industry. For instance, laser cutting technology not only realizes high-precision metal material cutting but also significantly improves production efficiency; laser welding technology can achieve seamless connections of metal materials, greatly enhancing the aesthetics and quality of products. Moreover, laser marking technology is widely used in product labeling and decoration. Meanwhile, the industry is exploring the use of new materials and technologies to create more innovative and personalized products to meet the market’s demand for high quality and unique designs. Although facing challenges such as intensified market competition and fluctuations in raw material prices, the watches and jewelry industry still shows strong vitality and great market potential, with considerable room for future development.

Manufacturing characteristics and technical difficulties in the watches and jewelry industry

Fine craftsmanship : The manufacturing of jewelry and watches requires fine craftsmanship and high skills. Each product is a perfect combination of art and engineering, requiring precise design and high-precision mechanical processing technology.

Noble materials : The industry often uses materials such as gold, platinum, diamonds, and other precious elements and minerals, which are high-value items. Therefore, great care is needed during the processing to minimize material loss.

Unique design : The jewelry and watches industry emphasize uniqueness and personalized designs. Designers need to fully understand the material characteristics and technological requirements to create one-of-a-kind products.

Customized production : Customers often expect customized products, which demands enterprises to offer flexible production lines and personalized services.

High precision : The production of jewelry and watches requires very high precision and technical content because any minor flaw can affect the overall quality and appearance of the product.

Minimizing material loss : During production, it is essential to minimize the loss of precious materials, both to reduce costs and to preserve these rare resources.

Technological innovation : To maintain a leading position in the industry, enterprises need to constantly innovate technologically and develop new production processes.

Environmental requirements : Companies must adhere to various environmental regulations and standards to ensure sustainable development.

Product applications and customer benefits analysis at YUPEC company

Precision Fiber Laser Cutting Machine (LCF0120)

Case 1 : Intricate Jewelry Design

- Product Applications : The LCF0120 enables intricate and complex designs in the jewelry sector, such as detailed metal pattern cutting and inlay techniques, meeting the high-quality demands of jewelry brands through its high-precision fiber laser cutting technology.

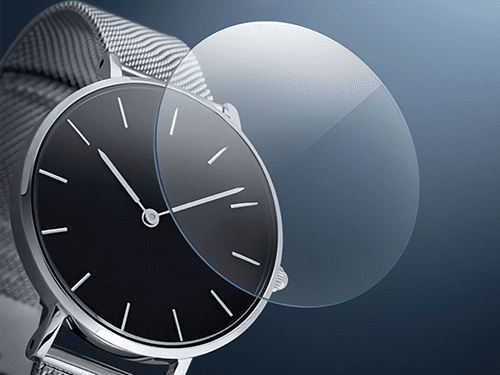

Case 2 : Watch Component Manufacturing

- Product Applications : The LCF0120 is capable of precisely cutting and manufacturing intricate watch components, such as casings and movement parts, with its highly precise cutting technology ensuring the accuracy and quality of the finished product.

Quality and Precision Assurance : The LCF0120 allows clients to maintain high standards of quality and precision in production, enhancing their brand reputation and market positioning.

Increased Production Efficiency : The high-speed laser cutting technology of LCF0120 can increase production efficiency, assisting clients in meeting tight deadlines with ease.

Cost-Saving : The LCF0120 aids in reducing manufacturing costs by optimizing resource utilization and minimizing waste, thereby increasing profitability.

Precision UV Laser Cutting (LCU0201)

Case 1 : High-Precision Gem Cutting

- Product Applications : The LCU0201, with its ultraviolet laser cutting technology, serves the gem industry for high-precision and complex gem cutting, allowing the crafting of more intricate and unique jewelry designs.

Case 2 : Fine Metal Surface Engraving

- Product Applications : The LCU0201 offers fine metal surface engraving services, creating unique and personalized watch and jewelry products, meeting the market’s demand for distinctive and individualized products.

High Precision :The LCU0201 guarantees high-precision cutting, which is vital in an industry where any minor error can have significant consequences.

Environmentally Friendly Production : The ultraviolet laser technology utilized in LCU0201 supports green manufacturing practices, producing less waste and energy consumption compared to traditional methods.

Improved Productivity : With its ability to carry out high-precision fast cutting, the LCU0201 significantly increases productivity, facilitating quicker product market entries.

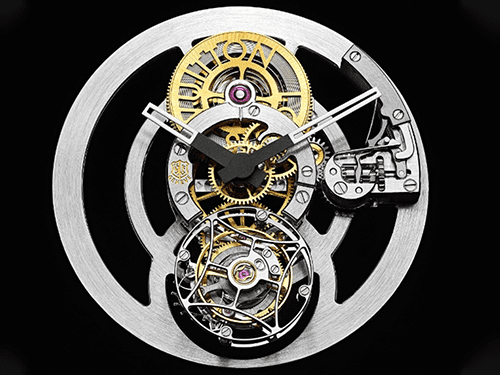

Apex Series - Laser Micromachining

Case 1 : Fine Watch Parts Processing

- Product Applications : Using the Apex Series laser micro-machining technology, it is possible to achieve fine processing and engraving of Watch micro gears, pointers, and other parts, ensuring their precision and quality, meeting the high standard requirements of the Watch industry.

Case 2 : Personalized Customization of Jewelry

- Product Applications : With the help of the high-precision laser engraving technology of the Apex Series, it can provide personalized design services for jewelry brands, such as fine patterns or text engraving on diamond or metal surfaces, enhancing the uniqueness and added value of the products.

Precision and Quality Assurance : By using Apex Series products, customers can achieve high precision and high-quality production, further strengthening their brand image and influence in the market.

Increased Product Added Value : Personalized customization services can provide customers with higher added value products, meeting the market’s demand for unique and personalized products.

Improved Production Efficiency : Laser micromachining technology can achieve rapid and efficient production, helping customers shorten the time to market and better seize market opportunities.

Axis Series - Precision Cutting

Case 1 : High-end Watch Case Manufacturing

- Product Applications : The Axis Series can achieve fine cutting and processing of high-end watch cases, ensuring their precision and aesthetics, meeting the quality requirements of high-end Watch brands.

Case 2 : One-Stop Jewelry Production

- Product Applications : The Axis Series provides a one-stop jewelry processing solution, including high-precision cutting, grinding, and polishing, greatly improving production efficiency and product quality.

Improved Quality and Efficiency : The Axis Series can help customers achieve high-quality and high-efficiency production, enhancing their competitiveness and influence in the market.

Save Costs and Time : The one-stop processing solution can save customers a lot of production time and costs, improving their market response speed.

Environmentally Friendly Production : By using the Axis Series laser cutting technology, customers can achieve environmentally friendly and low-waste production, meeting increasingly stringent environmental protection requirements.