Laser cutting is recognized as one of the metal processing methods with high efficiency, high quality, and high precision. There are many factors that affect laser cutting, and the nozzle is one of them. Choosing the right laser nozzle when cutting various materials can make processing simpler, so selecting the correct nozzle is crucial.

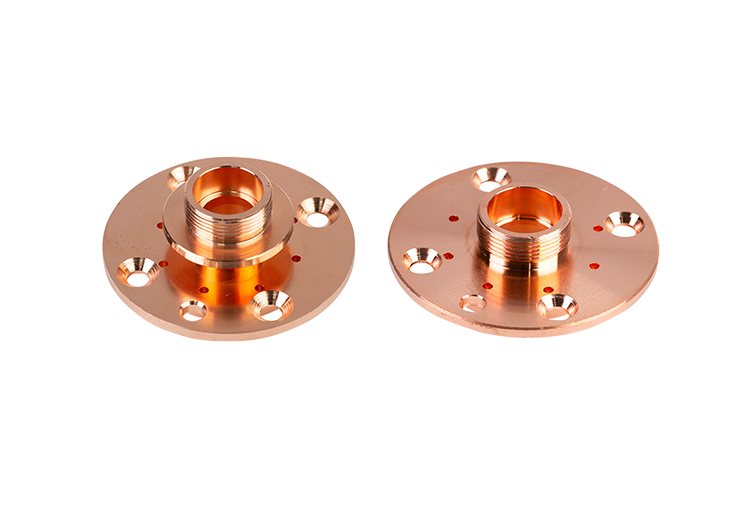

The nozzle is located at the bottom of the laser cutting head, where the laser beam and auxiliary gas act on the cutting material. Its main functions include gathering auxiliary gas to form high pressure, blowing away melted and vaporized material, preventing pollutants from bouncing back upwards, and protecting internal lenses.

Types of Laser Nozzles

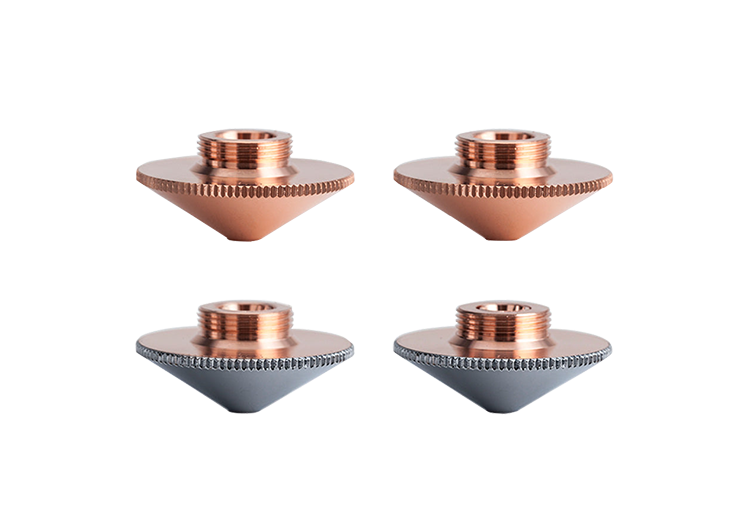

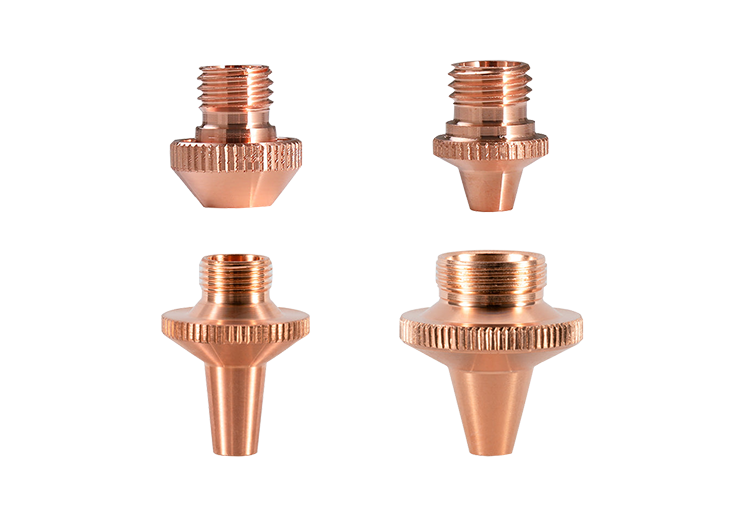

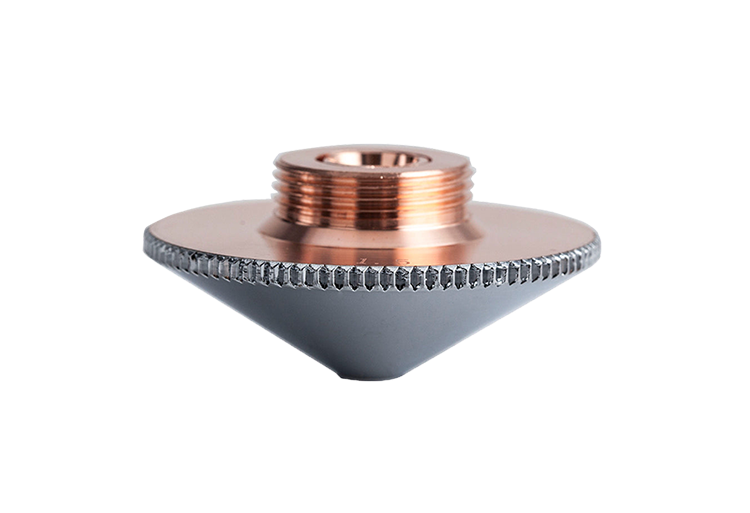

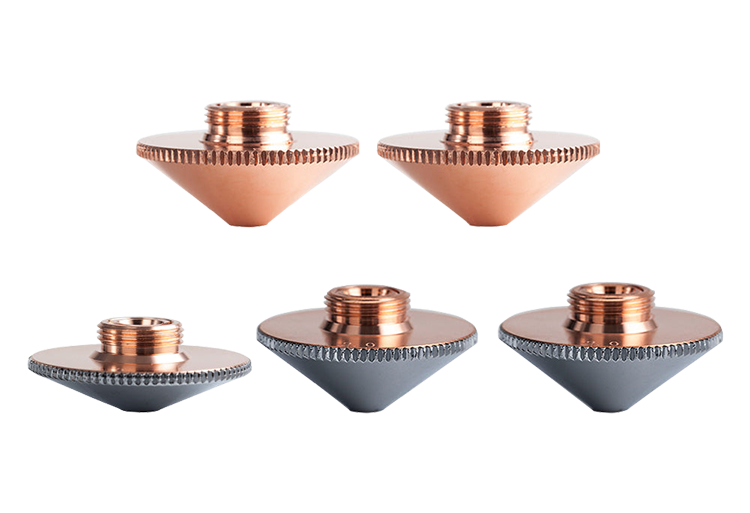

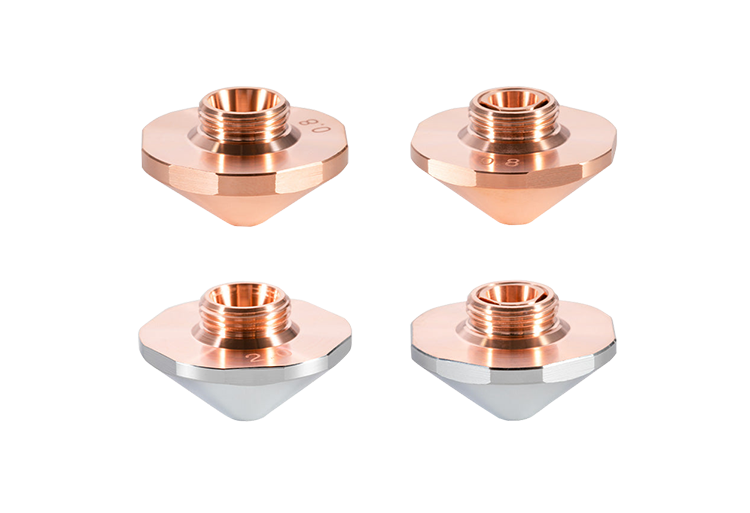

Laser cutting nozzles are divided into two types: single-layer and double-layer. Single-layer nozzles are used for melting cutting, such as when cutting materials like stainless steel, aluminum alloys, and brass, typically using nitrogen as the auxiliary gas. Double-layer nozzles are suitable for oxidation cutting, generally used for cutting carbon steel.

Materials of Laser Nozzles

There are two common materials for nozzles: purple copper and brass, with purple copper having better electrical conductivity and thermal conductivity than brass.

Expand to learn more

Sizes of Laser Nozzles

The aperture size of the nozzle determines the flow rate of the gas and the shape of the gas field. Generally, when cutting thin plates below 3mm, it is recommended to use a 1mm diameter nozzle; for thicknesses above 3mm, a 1.5mm diameter nozzle is recommended; and for materials above 10mm, a nozzle with a diameter of 2mm or more is recommended.

Processing Precision

A good laser head nozzle should have a concentricity of 0.03mm, while for nozzles with a size below 1.0mm, the concentricity should be even finer at 0.02mm. Nozzles with high precision concentricity can not only reduce the initial adjustment during processing but also effectively avoid damage to the inner wall of the laser head caused by high-energy lasers.

Send us a message

Don’t hesitate to ask, we usually reply in 24 hours or less!

Contact Information

Yupec Laser Germany GmbH

Itterpark 2, 40724 Hilden, Germany

- +49 2103 9674 492 / +49 2103 9676 682

Company Details

Yupec Laser Germany GmbH

Amtsgericht Jena, HRB 519333

Ust-Id~Nr. DE3552294798