A smart laser cutting machine represents a cutting-edge technological advancement that employs a focused laser beam to achieve highly precise and intelligent cutting of various materials. This innovative technology utilizes a high-energy density laser beam for cutting, ensuring not only exceptional accuracy but also integrating intelligent features for enhanced efficiency and adaptability. The smart laser cutting machine is distinguished by its ability to cater to diverse materials, including metals, plastics, glass, ceramics, and more, making it a versatile solution for modern manufacturing needs.

Advantages of Smart Laser Cutting Machines

Smart laser cutting machines redefine precision in cutting processes. The incorporation of intelligent systems and advanced algorithms ensures unprecedented accuracy and edge quality. The laser beam, guided by smart technology, adapts in real-time to material variations, ensuring consistent and precise cutting results.

These machines feature adaptive intelligence that allows them to dynamically adjust cutting parameters based on real-time feedback. This adaptability is crucial when working with materials of varying thicknesses, ensuring optimal cutting performance without the need for manual intervention.

Smart laser cutting machines are equipped with sophisticated monitoring and analytics capabilities. Real-time data collection enables continuous monitoring of the cutting process, identifying potential issues and optimizing performance. This data-driven approach enhances efficiency and contributes to predictive maintenance.

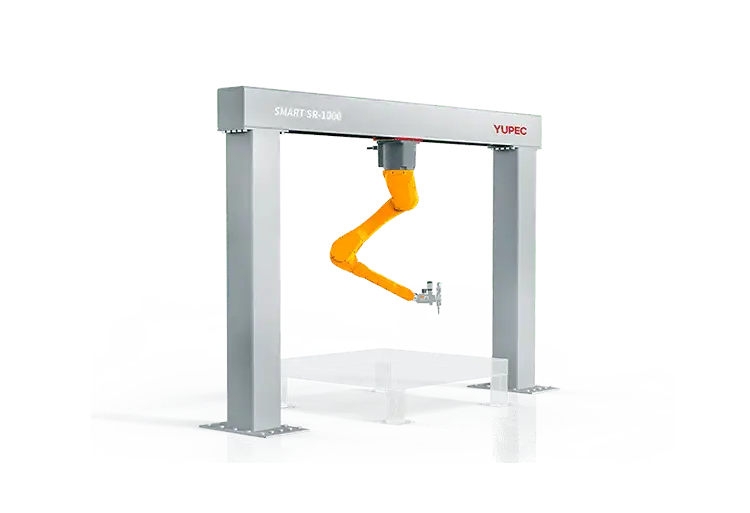

Integrated CNC components and automation capabilities make smart laser cutting machines an integral part of automated manufacturing processes. The synergy between intelligent cutting and automation streamlines operations, reduces dependency on manual labor, and enhances overall production efficiency.

Safety is paramount in manufacturing environments. Smart laser cutting machines come with enhanced safety features, including intelligent sensors and real-time hazard detection. This ensures a safer working environment by proactively addressing potential risks and minimizing the likelihood of accidents.

Expand to learn more

Applications of Smart Laser Cutting Machines

Smart laser cutting machines find applications across diverse industries, providing a solution that combines precision with intelligent functionality. Here are key application areas and associated materials:

Electronics and Semiconductor Manufacturing

In the electronics industry, smart laser cutting machines are indispensable for precise cutting of circuit boards and semiconductor components. The adaptive intelligence ensures optimal cutting performance on materials like silicon, ceramics, and glass.

Automated Fabrication in Automotive Industry

Smart laser cutting plays a vital role in the automated fabrication of intricate components for the automotive sector. The ability to adapt to different materials, including metals and composites, makes it suitable for cutting various parts with high precision.

Advanced Medical Device Production

Precision is critical in the production of medical devices. Smart laser cutting machines are used for manufacturing intricate medical instruments, implants, and components. The real-time monitoring capabilities contribute to maintaining stringent quality standards.

Aerospace Component Manufacturing

The aerospace industry benefits from the adaptability of smart laser cutting machines in manufacturing aircraft parts and engine components. The ability to cut high-strength metal alloys, titanium alloys, and composite materials with intelligence ensures optimal results.

Customized Furniture Production

In the furniture manufacturing sector, smart laser cutting machines enable highly customized and intricate designs on wood, plywood, and other materials. The adaptive intelligence ensures precise cutting for unique and complex furniture pieces.

Architectural Metalwork in Construction

Smart laser cutting is applied in the construction industry for creating intricate metal structures and decorative elements. The ability to adapt cutting parameters based on real-time analytics ensures the efficient production of complex designs.

Send us a message

Don’t hesitate to ask, we usually reply in 24 hours or less!

Contact Information

Yupec Laser Germany GmbH

Itterpark 2, 40724 Hilden, Germany

- +49 2103 9674 492 / +49 2103 9676 682

Company Details

Yupec Laser Germany GmbH

Amtsgericht Jena, HRB 519333

Ust-Id~Nr. DE3552294798