Biotechnology & Medical Industry

Manufacturing Characteristics, Technical Specifications, and Technical Challenges in the Medical Equipment and Biotechnology Equipment Industry:

In the medical equipment and biotechnology equipment industry, the manufacturing of devices needs to comply with a series of strict technical specifications and standards to address diverse and highly complex technical challenges. These technical specifications mainly encompass precise material selection, advanced manufacturing techniques, stringent quality control, and innovative design approaches. The technical challenges include complex production processes, high manufacturing costs, strict compliance requirements, and rapid technology updates.

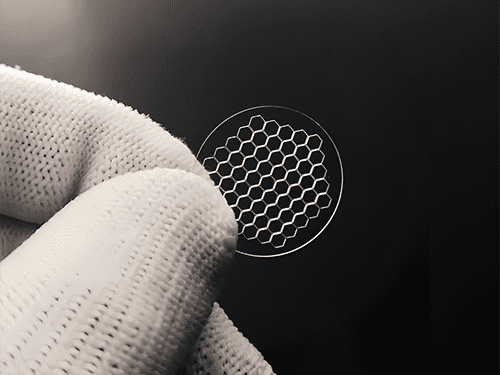

The manufacturing features of medical devices cover various aspects from micro-fabrication to precision manufacturing, relying on advanced and biocompatible materials such as medical-grade stainless steel, titanium, and medical plastics. These devices often require a high degree of precision and functional complexity, and achieving this necessitates the use of advanced manufacturing technologies like Micro-Electro-Mechanical Systems (MEMS). Moreover, the industry also emphasizes continuous research and development and innovation to adapt to the rapid changes in the industry and meet the needs of patients. Simultaneously, personalized and customized solutions are increasingly focused on, especially rapid prototype manufacturing and individualized production achieved through digitization and 3D printing technologies.

YUPEC Company Product Applications and How Can They Benefit You?

APEX Series - Laser Micro-Machining

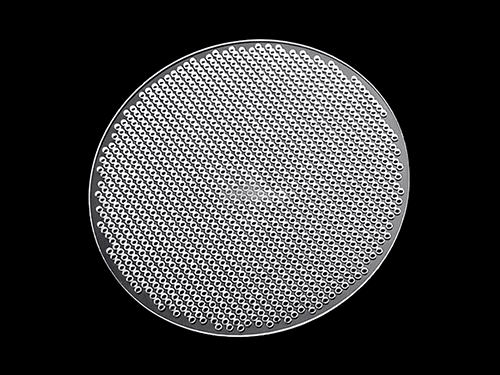

- High Precision : Capable of achieving micro-level fine processing.

- High Speed : Superior laser output speed ensures high-efficiency machining.

- Multi-functionality : Can carry out various laser machining operations such as marking, etching, cutting, etc.

- Waste Reduction : High precision processing reduces material waste, lowering costs.

- Accelerated Market Entry : High-speed processing can shorten the product development cycle.

- Flexible Production : Multi-functionality allows for quick shifts between different production demands, adapting to a changing market.

AXIS Series - Precision Cutting

- Accurate Cutting : Provides precise and accurate cutting across a variety of materials.

- Stability : Maintains stable performance and accuracy during long working hours.

- Automation : Equipped with an intelligent control system, supporting automated production.

- Increased Output : High stability and automation features ensure high production output.

- Reduced Maintenance Costs : Intelligent control system can reduce the workload of maintenance personnel.

- Quality Assurance : Precise cutting ensures high quality and consistency of products.

Precision Fiber Laser Cutting Machine LCF0120

- Broad Material Compatibility : Capable of efficiently cutting a wide range of materials.

- High Efficiency : Provides fast and accurate cutting solutions.

- Environmental Friendly : Fiber laser cutting reduces environmental pollution and resource waste.

Energy-Saving and Eco-Friendly : Lower energy consumption and reduced material waste.

Excellent Cutting Results : Efficient and precise cutting abilities ensure excellent cutting outcomes.

Accelerated Investment Return : Rapid and efficient cutting abilities can accelerate the investment return cycle for clients.

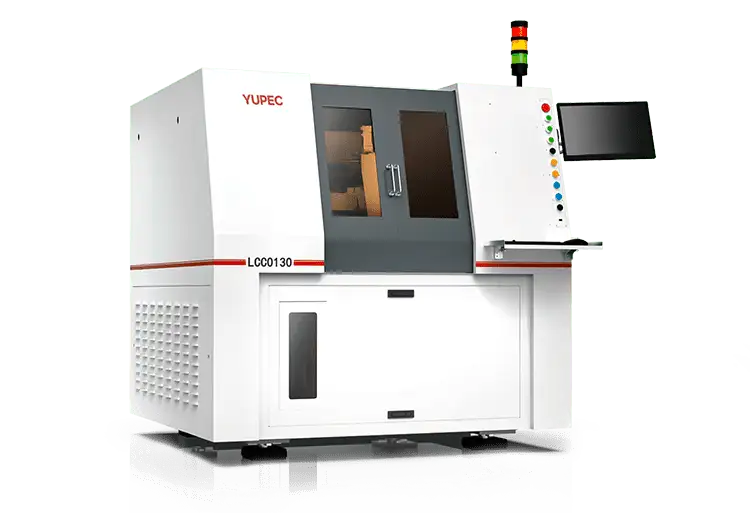

Precision CO2 Laser Cutting Machine LCC0130

- High Power : Offers strong laser output, capable of handling various hard-to-process materials.

- Fine Processing : Capable of achieving high precision and quality cutting results.

- Environmentally Safe : Low noise and low pollution working environment.

Reduced Post-Processing : Fine processing reduces the need for post-processing of products, lowering costs.

Enhanced Competitiveness : High-quality processing results can enhance product market competitiveness.

Green Production : Low pollution production method assists companies in achieving green production goals.