Table of Contents

Two Methods for Implementing the Fish Scale Pattern

The classification of copper nozzles mainly depends on: whether wire feeding is involved, the size of the welding wire, and the welding angle. For example, for inner angle wire feeding welding with 1.0mm welding wire, use the AS-12 copper nozzle as shown in the diagram.

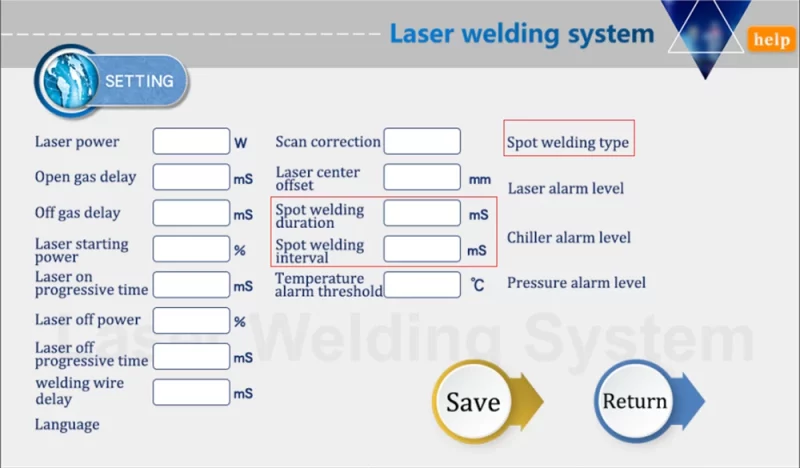

Using the System's Built-in Spot Welding Function

1. Fish scale welding mode

1.1 Enable spot welding mode on the home page.

1.2 In the settings, choose the type of spot welding (fish scale pattern).

1.3 Set reasonable spot welding duration and spot welding interval in the settings.

In this mode, only the laser is turned off when in the intermittent, and other settings such as switching on or switching off light time do not affect and do not take effect, so the damage to the protective lens may increase.)

Simply set the spot welding duration and interval to achieve the fish scale welding effect (minimum setting is 1ms).

Example:

- Spot Welding Duration: 150ms (this parameter affects the size of the welding pattern)

- Spot Welding Interval: 50ms (this parameter affects the interval between two patterns)

2. Intermittent welding mode

In this mode, please turn off the laser, the shielding gas, and stop wire feeding when in the intermittent. The other parameters such as the time of switching on or off are mainly used for fix length welding.

Change the welding length by setting the spot welding duration, and the spot welding interval can be set higher.

Example:

- Spot Welding Duration: 1000ms (this parameter affects the welding length, i.e., the time of laser emission)

- Spot Welding Interval: 5000ms (this parameter can be a fixed value, default is 5000)

Please pay attention that in this mode, it needs to be artificially judged whether the wire is broken or not, and the wire needs to be lifted up in time.

Wire Feeder Pulse Welding

Without making changes to the system, under normal welding mode, switch to pulse mode using the wire feeder and set the pulse frequency and smoothing.