Table of Contents

Stainless steel is a commonly used metal material in daily life, with applications ranging from sinks, thermos cups, doors and windows, kitchen and bathroom appliances, to office kitchenware. In the process of stainless steel processing, welding is often required to achieve the connection between workpieces. In this processing step, using a handheld laser welder for stainless steel welding is a good choice.

Characteristics of Stainless Steel

Stainless steel refers to steel with a chromium content of more than 12%. Chromium in steel forms a solid and dense Cr2O3 film on the surface, isolating the steel from the atmosphere or corrosive media, preventing corrosion. By adding a certain amount of elements such as Ni, Ti, Nb, W, etc., various types of stainless steel with special corrosion resistance, high-temperature oxidation resistance, or certain high-temperature strength can be formed.

The main characteristics of stainless steel materials are as follows:

Corrosion Resistance

Stainless steel materials have excellent corrosion resistance, maintaining stability and durability in harsh environments.

High-Temperature Strength

Stainless steel materials exhibit excellent high-temperature strength and heat resistance, maintaining good physical and chemical properties in high-temperature environments.

Aesthetic Appeal

Stainless steel materials have good surface finish and gloss, widely used in architecture and decoration.

Wear Resistance

Stainless steel materials have excellent wear resistance, resisting friction, abrasion, and corrosion.

Tensile Strength

Stainless steel materials have high tensile strength, able to withstand significant external forces, exhibiting excellent mechanical properties.

Drawbacks of Traditional Stainless Steel Welding Methods

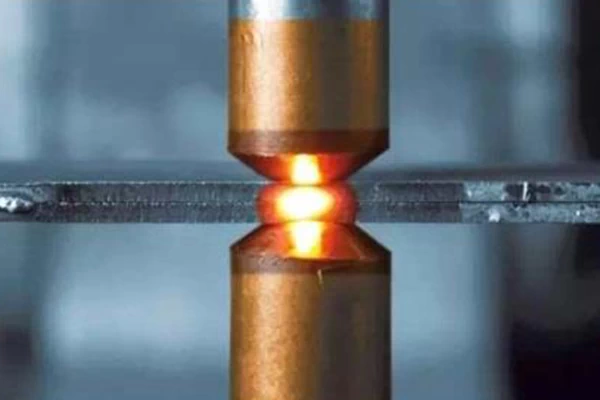

There are two main traditional methods for stainless steel welding: tungsten inert gas (TIG) welding and resistance spot welding.

Disadvantages of Tungsten Inert Gas (TIG) Welding

- Introduction of a heat-affected zone during welding, affecting material properties.

- TIG welding produces wider weld seams, requiring additional processing to meet certain application requirements.

- Generation of a significant amount of smoke during welding, posing health risks.

Disadvantages of Resistance Spot Welding:

- Lack of reliable detection methods.

- Generation of sparks during welding, posing a high risk of danger.

- Complexity of equipment and the need for sophisticated control systems and professional skills, resulting in higher equipment and operational costs.

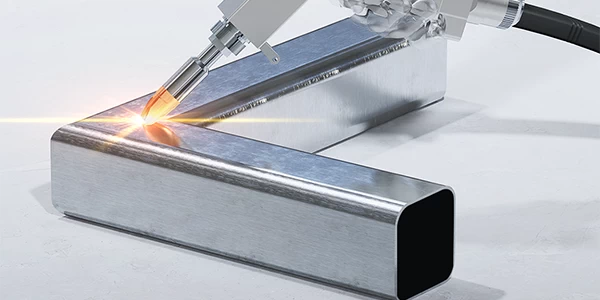

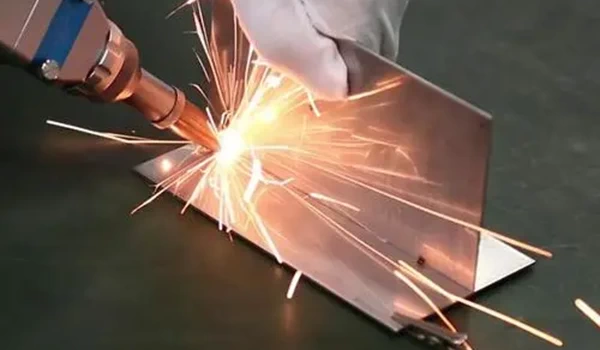

Advantages of Handheld Laser Welder for Stainless Steel

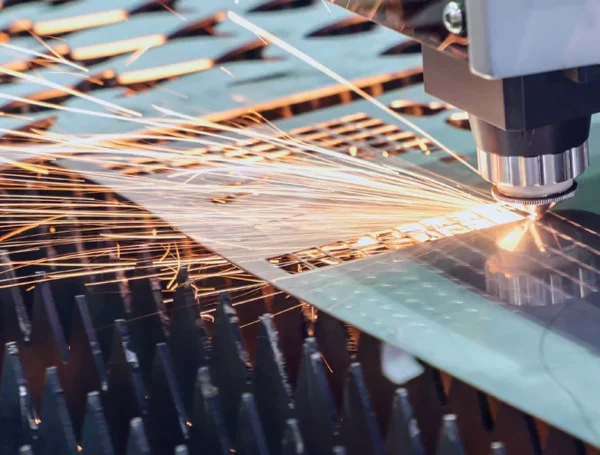

A handheld laser welder utilizes high-energy laser pulses to locally heat materials within a small area. The energy radiated by the laser diffuses into the material’s interior through heat conduction, melting the material to form a specific molten pool for welding purposes. The use of laser welding on stainless steel offers numerous advantages:

Applications of Stainless Steel Products

Stainless steel, known for its corrosion resistance, high-temperature resistance, and durability, finds widespread applications in various areas of daily life. Here are some examples of daily applications of stainless steel:

Kitchen Utensils

– Pots and Pans: Stainless steel pots offer excellent corrosion resistance, even heat distribution, and ease of cleaning.

– Cutlery and Tableware: Stainless steel cutlery remains sharp for an extended period and is resistant to rust.

Furniture

– Tables, Chairs, and Sofas: Stainless steel frames provide durability and stability to furniture, both indoors and outdoors.

Construction and Decoration

– Doors, Windows, and Handrails: Stainless steel is widely used in the construction of elements such as doors, window frames, and handrails, thanks to its corrosion resistance and modern appearance.

Medical Equipment

– Medical Instruments and Dental Tools: Stainless steel’s corrosion resistance and hygienic properties make it ideal for manufacturing surgical instruments, instrument trays, and dental tools.

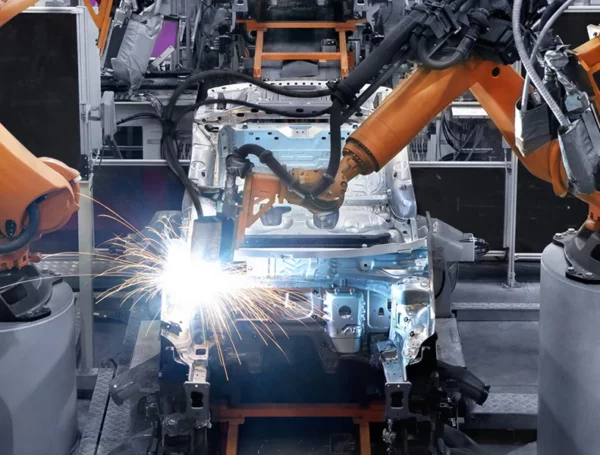

Automobiles and Transportation

– Exhaust Pipes and Body Parts: Stainless steel is used in manufacturing exhaust pipes and body parts for automobiles, enhancing durability and extending the lifespan of vehicles.

Overall, stainless steel’s wide-ranging applications stem from its corrosion resistance, durability, easy cleaning, and modern appearance. In these everyday applications, stainless steel plays a crucial role, providing users with high performance and reliability.

Future Development Trends

Handheld laser welders, as an advanced welding technology, show several key trends for future development, further promoting their widespread application in the manufacturing of stainless steel products.

Technological Innovation and Improvement

Rapid technological advancements will lead to continuous innovation and improvement in handheld laser welding technology. Next-generation laser sources, smarter control systems, and more precise welding head designs will enhance the performance, expanding its application range and efficiency.

Diversified Application Fields

As handheld laser welding technology matures, its application will extend beyond current manufacturing sectors. In the future, this technology is expected to find use in aerospace, energy, electronics, and other industries, becoming a crucial process for producing high-quality stainless steel products.

Enhanced Intelligence and Automation

Advancements in artificial intelligence and automation will enable handheld laser welders to achieve higher levels of intelligence. Intelligent welding systems, capable of learning and adapting, will automatically adjust welding parameters to optimize welding effects, reducing dependence on operator skills and improving production consistency and controllability.

Portable and Flexible Design

To accommodate diverse working environments, future handheld laser welders will focus on lightweight and user-friendly designs. This will enhance portability for various scenarios, including welding tasks in narrow spaces and on moving workpieces.

Environmental Protection and Energy Efficiency

Growing societal awareness of environmental protection will drive future handheld laser welders to focus on reducing energy consumption and minimizing waste production. Measures such as adopting more efficient laser sources and improving material utilization rates will be key directions for future development.

Summary

The application of handheld laser welders in the manufacturing process of stainless steel products demonstrates outstanding advantages, with high-quality and efficient welding processes making it highly sought after in various application areas. With continuous technological progress and increasing market acceptance, handheld laser welders are poised for wider future applications. For stainless steel manufacturers pursuing high-quality and efficient production, investing in handheld laser welding technology may be a viable long-term strategy.