Table of Contents

A laser marking machine is a precision tool used to mark various materials’ surfaces. These marks can include text, images, QR codes, barcodes, and more, with characteristics of high precision, high speed, non-contact operation, permanence, and programmability. When choosing a laser marking machine, it’s essential to understand its types, advantages, applications, market conditions, and purchasing tips.

What is a Laser Marking Machine?

A laser marking machine is a device that uses a high-energy laser beam to mark various materials’ surfaces. These materials can include metals, plastics, ceramics, glass, leather, and more. The marks made by laser marking machines are typically permanent and do not require the use of ink or chemicals.

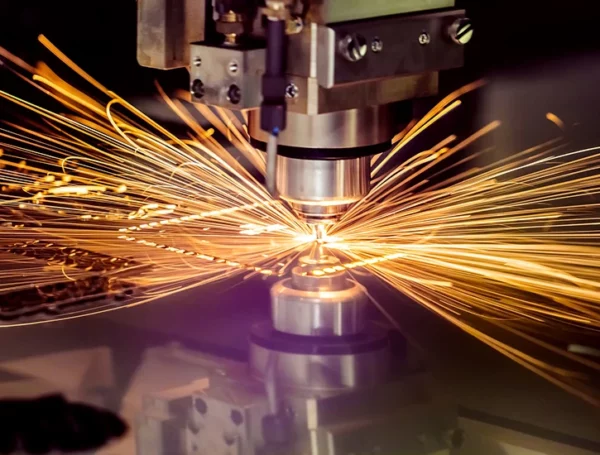

How Laser Marking Machines Work

Laser marking machines operate based on laser technology. A laser marking machine generates a high-energy laser beam and focuses it on a tiny focal point. When the laser beam interacts with the material’s surface, it can induce various physical or chemical changes, including evaporation, oxidation, ablation, or color change, thus achieving marking.

Main Types of Laser Marking Machines

As you explore the market for a laser marking machine, it’s essential to understand the variety of options available, each suited to specific applications and materials. The three primary types are:

- Fiber Laser Marking Machine:

Fiber laser marking machine primarily finds its technical applications in plastic, electronics, metal, ceramics, tobacco, and various materials. It is used to mark and engrave a wide array of information graphics, including text, images, and barcodes, meeting the specific needs of these industries. The simplicity, speed, and convenience of operating fiber laser marking machines, coupled with their rapid and clear marking capabilities, continuously enhance the efficiency of production management for businesses.

- UV Laser Marking Machine:

UV laser marking machine is employed in industries similar to those served by fiber laser marking machines. However, its distinct advantage becomes apparent when some products require marking effects that fiber laser machines cannot achieve. UV laser marking machines fall under the category of cold light, making them suitable for applications where fiber lasers might fall short. Due to this characteristic, UV laser marking machines can often meet the requirements that many other products cannot satisfy, ensuring satisfying marking effects on various materials.

- CO2 Laser Marking Machine:

CO2 laser marking machines primarily use CO2 laser tubes as the laser source and are suitable for non-metallic materials like wood, plastics, rubber, and glass. They are popular in some applications due to their cost-effectiveness and good marking quality.

Advantages of Laser Marking Machines

In addition to these types, laser marking machines offer several advantages that make them highly sought after in the manufacturing and marking industries:

High Precision

Laser marking machines offer exceptionally high marking precision, typically ranging from a few micrometers to sub-millimeters. This makes them invaluable for applications requiring high marking precision.

High Speed

Laser marking machines complete marking tasks quickly, significantly enhancing production efficiency, especially in large-scale production and high-output manufacturing.

Non-contact Operation

Laser marking is a non-contact process that does not require direct contact with the material's surface, reducing wear and contamination risks, thereby ensuring material quality.

Programmability

Laser marking machines can be programmed to perform various types of marking, including text, images, barcodes, QR codes, making them highly flexible.

Permanence

Laser marking results are typically permanent and cannot be easily erased or altered, which is crucial for product identification and anti-counterfeiting.

Automation

Laser marking machines can often be integrated with computer control systems to automate the marking process, reducing the potential for human error and improving efficiency.

Environmental Friendly

Laser marking machines typically do not produce waste as the marking process is non-physical contact and does not generate cuttings, wear, or chemical residues. For some types of laser marking machines like CO2 laser markers, emissions are managed with appropriate exhaust control and filtration systems to minimize environmental impact.

Applications of Laser Marking Machines

Laser marking machines find diverse applications across industries, enabling precise, permanent, and non-contact marking on various materials. Common applications include product identification, traceability, quality control, and anti-counterfeiting measures. They are widely used in manufacturing, electronics, medical devices, jewelry, woodworking, and more, offering customized, high-quality marking solutions for a broad range of products and materials.

Manufacturing Industry

Laser marking machines are widely used in automotive manufacturing, electronic manufacturing, aerospace, etc., for marking parts, product identification, batch tracking, product traceability, and quality control.

Medical Industry

In the medical device manufacturing sector, laser marking machines are used to mark surgical instruments, implants, and medical packaging to ensure product traceability and safety.

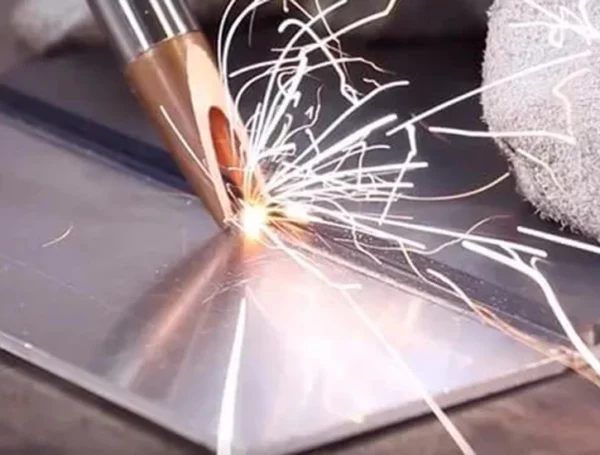

Stainless Steel Doors and Windows

During the manufacturing of stainless steel doors and windows, handheld laser welders are used to weld the frames, ensuring structural stability and a smooth, appealing weld seam.

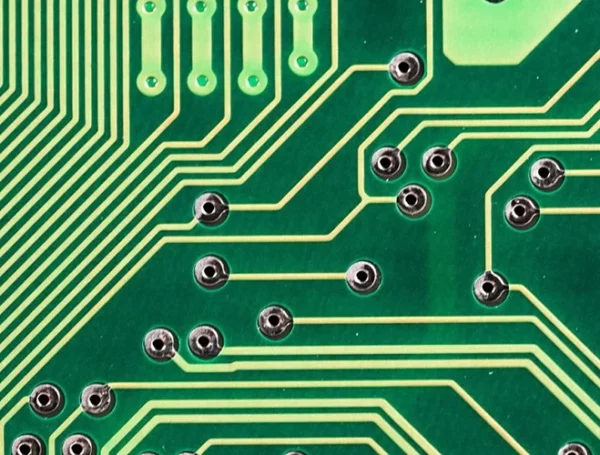

Electronics Industry

Laser marking machines are used to mark electronic components, circuit boards, and electronic products for identification and anti-counterfeiting purposes.

Jewelry Industry

In the jewelry industry, laser marking machines are used to engrave jewelry, diamonds, and precious metals to ensure product authenticity and brand protection.

Woodworking and Leather Products

Laser marking machines are employed to mark wooden furniture, leather products, and crafts for added personalization and decorative effects, providing designers and manufacturers with greater creative freedom to customize unique products.

Laser Marking Machine Market

Accoring to the report, laser Marking Machine Market size was valued at USD 3.2 billion in 2022 and is anticipated to grow at a CAGR of over 90 between 2023 and 2032. The laser marking machine market is continually growing globally, particularly in manufacturing, electronics, and medical sectors. It is a competitive market with numerous well-known manufacturers offering various laser marking machine models. Consumers need to consider factors like performance, pricing, after-sales support, technological innovation, and reliability when selecting the right equipment.

Tips for Choosing a Laser Marking Machine

When buying a laser marking machine, it is essential to carefully consider the following factors:

Define Your Requirements

Clearly define your requirements before purchasing a laser marking machine. Consider factors such as the type of material you will be marking, required marking precision, marking speed, budget, and expected production volume.

Material Compatibility

Different types of laser marking machines are suitable for different materials. Ensure that the machine you choose is compatible with the material you intend to mark, whether it's metal, plastic, glass, ceramic, or other materials.

Balance Precision and Speed

When selecting a laser marking machine, it's necessary to balance precision and speed. Higher precision often comes with lower marking speed, while higher speed may reduce marking precision. Find the right balance according to your application requirements.

Maintenance Costs

Understand the maintenance costs of the equipment, including laser source replacement, optical component maintenance, and parts replacement. This helps in planning the overall operational cost of the machine.

Safety

Ensure that the laser marking machine you purchase complies with laser safety standards and take appropriate safety measures to protect operators from laser radiation. Proper training of operators on the correct use of laser equipment is also crucial.

After-Sales Support and Warranty Policies

Choose a reputable manufacturer that provides good after-sales support and reasonable warranty policies. This ensures that you can get timely repairs and support in case of equipment issues.

Technological Innovation

Check if the manufacturer is continuously innovating its technology. New technologies and features can improve equipment performance and functionality, thereby increasing production efficiency.

Compliance

Ensure that the laser marking machine complies with regulations and standards in your region. This includes laser safety, electromagnetic compatibility, and environmental regulations.

Conclusion

Laser marking machines are powerful tools known for their high precision, high speed, non-contact operation, programmability, permanence, and environmental friendliness. They find applications in various industries, from automotive manufacturing to medical device manufacturing, electronics, jewelry, woodworking, and more.

When purchasing a laser marking machine, it’s important to consider factors like material compatibility, precision, speed, maintenance costs, safety, after-sales support, and technological innovation. Choosing the right equipment that fits your requirements will help improve production efficiency and ensure marking quality.

As technology continues to evolve, laser marking machines will continue to play a pivotal role in manufacturing, driving innovation and efficiency improvements. Whether you are a manufacturer, engineer, or entrepreneur, understanding the different types of laser marking machines, their applications, and purchasing advice will help you make informed decisions to meet your specific needs.