Table of Contents

When it comes to cleaning dirt, removing coatings, or preparing surfaces, laser cleaning machines have become a highly regarded technology. These high-tech devices use laser energy for cleaning, replacing traditional chemical cleaning, sandblasting, and other methods. In this article, we will explore the working principles of laser cleaning machines, their advantages, application areas, and tips for selecting the right laser cleaning machine, to help you better understand this advanced technology.

A laser cleaning machine is a device that utilizes laser energy to remove impurities, dirt, and coatings. In comparison to traditional cleaning methods, laser cleaning machines use a highly precise laser beam to remove unwanted substances from surfaces without damaging the underlying material. The principle behind this technology lies in the high energy of laser photons, enabling it to break down, evaporate, or push dirt away from the surface without the need for chemical solvents or physical contact.

How Does a Laser Cleaning Machine Work?

The working principle of a laser cleaning machine is relatively simple, but its effectiveness is remarkable. A laser cleaning machine first generates a laser beam and then focuses this beam onto the surface that needs cleaning. The energy of the laser beam interacts with impurities or coatings on the surface, leading to their removal or evaporation. This process typically involves the following key steps:

- Energy Absorption: The energy of the laser beam is absorbed by impurities or coatings on the target surface.

- Evaporation or Decomposition: The absorbed laser energy causes dirt or coatings to evaporate or decompose into gas or solid particles.

- Removal: The evaporated or decomposed impurities are pushed away from the surface, leaving it clean.

- Collection: Some laser cleaning machines are equipped with particle collection systems to capture and process the generated particles or gases.

Advantages of Laser Cleaning Machines

Laser cleaning machines, as an advanced cleaning technology, offer numerous advantages that make them highly popular in various applications:

No Need for Chemical Cleaning Agents

Laser cleaning machines do not require the use of chemicals, thus eliminating the generation of waste or chemical wastewater, which contributes to environmental protection.

High Efficiency Cleaning

Laser energy is highly precise, capable of rapidly removing various types of dirt, paint, coatings, and oxides. It is faster and more efficient than traditional cleaning methods.

Non-Contact Cleaning

Laser cleaning is non-contact, causing no mechanical wear or scratches, making it suitable for cleaning fragile surfaces or complex geometries. High Precision and Controllability: Cleaning depth and intensity can be controlled by adjusting laser parameters to meet the requirements of different applications.

Time and Labor Saving

Laser cleaning machines can significantly increase cleaning speed, reducing manual intervention and saving time and labor costs.

No Secondary Pollution

Since no chemicals are used, laser cleaning does not introduce secondary pollution, making it ideal for high-purity applications such as semiconductor manufacturing.

Suitable for Various Materials

Laser cleaning can be applied to metals, plastics, ceramics, stone, and various other materials, making it a versatile cleaning solution.

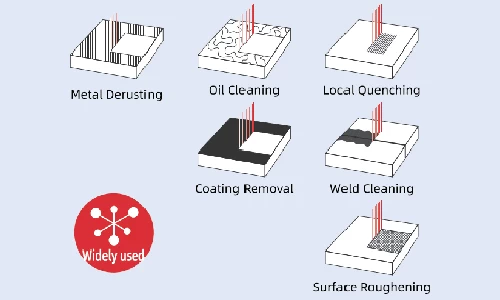

Applications of Laser Cleaning Machines

The applications of laser cleaning machines extend far beyond the previously mentioned areas. Here are more detailed descriptions of some key application areas:

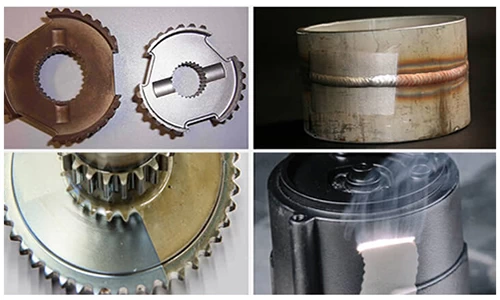

Industrial Manufacturing

Laser cleaning machines are used in various industrial manufacturing processes to clean and prepare workpiece surfaces, such as metal parts, plastic products, and glassware. This helps improve product quality and production efficiency.

Aircraft Maintenance and Repair

Aviation maintenance organizations use laser cleaning machines to remove dirt, coatings, and corrosion from aircraft surfaces, enhancing aircraft performance and safety.

Energy Industry

In energy production, laser cleaning machines are employed to clean turbine blades, boiler pipes, and solar panels, improving efficiency and prolonging equipment life.

Healthcare and Medical

Thorough cleaning and sterilization of medical equipment, surgical instruments, and dental tools are critical. Laser cleaning machines help maintain high levels of hygiene in these fields.

Electronics Manufacturing:

Laser cleaning machines are used to clean printed circuit boards, electronic components, and precision instruments, ensuring the reliability of electronic equipment.

Construction and Cultural Heritage:

In building cleaning and cultural heritage preservation, laser cleaning machines are widely used to remove dirt, deposits, and coatings, restoring the original appearance of structures and artifacts.

Food Processing Equipment

The food processing industry uses laser cleaning machines to clean food processing equipment, preventing cross-contamination and ensuring product quality.

Stone and Sculpture

In stone carving and sculpture, laser cleaning machines effortlessly remove stains, dirt, and oxides, restoring the original appearance of artworks.

Tips for Choosing the Right Laser Cleaning Machine

When selecting a laser cleaning machine, it’s essential to delve into the following aspects:

Detailed Understanding of Cleaning Requirements

Before purchasing a laser cleaning machine, it's crucial to have a clear understanding of your cleaning requirements, including the type of materials to be cleaned, surface characteristics, impurity or coating type and thickness, required cleaning speed, and cleaning depth. A profound understanding of these needs will help determine the specifications and performance requirements of the necessary laser cleaning machine.

Choice of Laser Source and Wavelength

Different types of laser cleaning machines use different laser sources, such as Nd:YAG lasers, carbon dioxide (CO2) lasers, and others. Each type of laser has distinct wavelengths and power levels, suitable for different cleaning tasks. For example, Nd:YAG lasers are effective for metal surfaces, while CO2 lasers are suited for non-metal materials.

Balancing Power and Energy Density

Selecting the appropriate laser power and energy density is crucial. Higher laser power can lead to faster surface cleaning, but it may risk over-cleaning or causing damage. Balancing cleaning speed and quality requires choosing the right power and energy density based on your needs.

Beam Focusing and Adjustment

Cleaning effectiveness is also linked to the focusing and adjustment of the laser beam. Some laser cleaning machines feature adjustable beam diameters and focal lengths, enabling finer control. Ensure that the equipment you choose has the necessary beam adjustment capabilities to meet various cleaning requirements.

Level of Automation

Consider the degree of automation of the cleaning machine. Highly automated machines are typically easier to operate, reducing the skill requirements for operators. This is particularly important in large-scale production environments to improve production efficiency.

Supplier Selection

Choose a reliable supplier or manufacturer, ensuring they provide excellent after-sales service and support. Determine if they offer customized solutions to meet your specific requirements. Review the supplier's reputation and customer feedback to ensure you select a trustworthy partner.

Operator Training

Ensure that your operators receive proper training to understand how to operate the laser cleaning machine correctly and safely. Operator skills and knowledge are vital for the effective use of the equipment.

Performance Testing and Verification

After acquiring the equipment, perform performance tests and verification to ensure it meets the expected cleaning results and quality standards. This includes testing cleaning speed, removal rates, and surface quality.

Cost-Benefit Analysis

Lastly, conduct a cost-benefit analysis, considering the total ownership cost of the equipment, including purchase costs, maintenance expenses, energy consumption, and more, in relation to its performance and benefits. This will help determine if the equipment aligns with your budget and long-term needs.

Conclusion

In conclusion, laser cleaning machines are an advanced cleaning technology with characteristics of efficiency, environmental-friendliness, and precision, making them suitable for various applications. By understanding their working principles, advantages, application areas, and the tips for selecting the right machine, you can make informed decisions to meet your cleaning requirements and bring benefits to your production and maintenance processes. Whether you are an industry professional or a hobbyist, laser cleaning machines offer a more efficient and sustainable cleaning solution.