Table of Contents

In the market, there are two common types of laser cutting machines: fiber laser cutting machines and CO2 laser cutting machines. Many people are often confused about the differences between these two devices and how to choose between them. In fact, there are significant differences between fiber laser cutting machines and CO2 laser cutting machines. This article will explore the working principles, cutting capabilities, cost-effectiveness, usage and maintenance, environmental and safety aspects, and application areas of these two types of cutting machines, to help readers better understand the comparison between them.

Fiber vs CO2 Laser Cutter - Working Principles

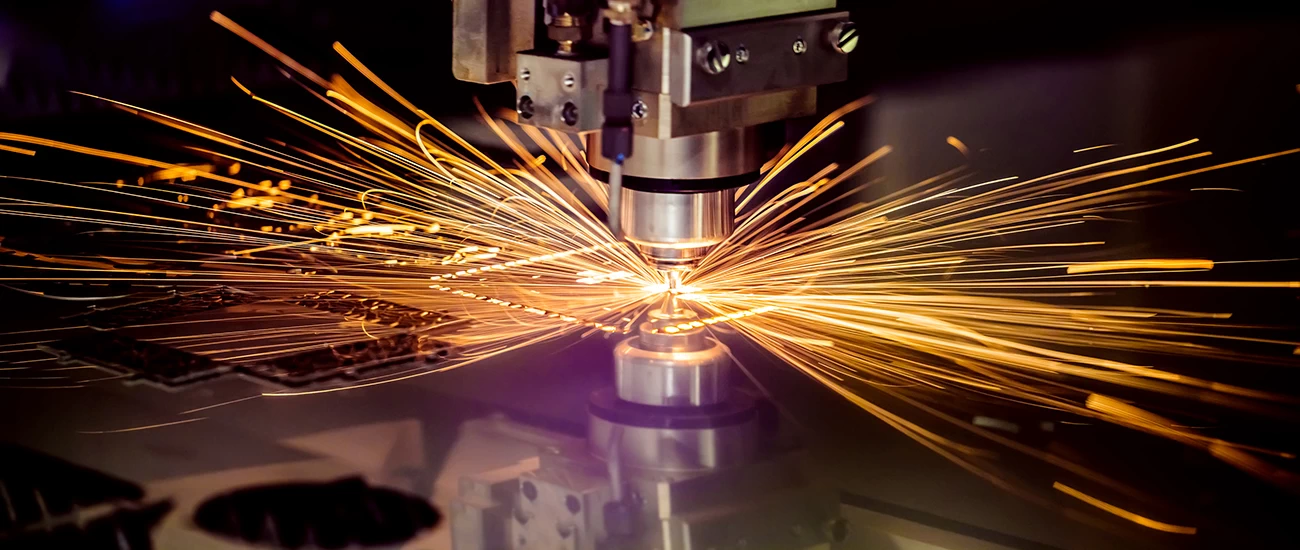

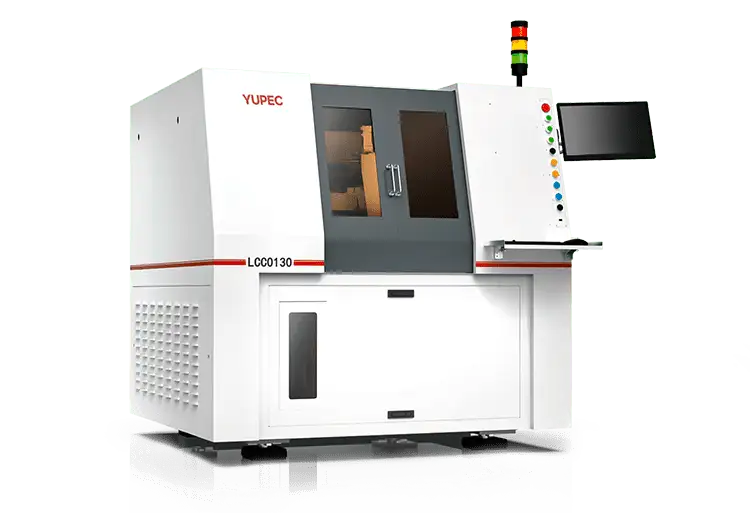

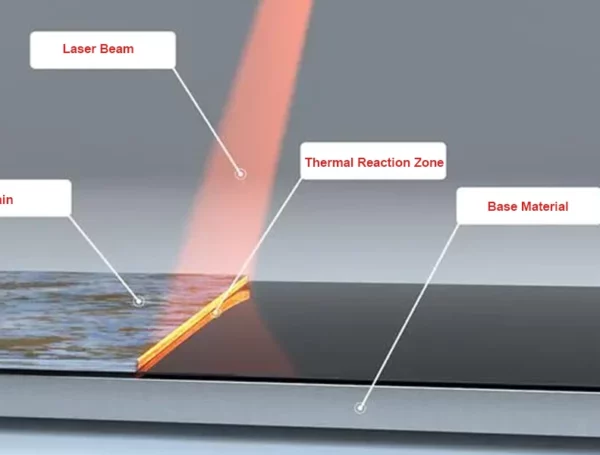

Fiber Laser Cutting Machine: Fiber laser cutting machines use a high-energy fiber laser beam focused on a small spot to melt and vaporize material on the workpiece’s surface. This process is computer-controlled to ensure cutting precision and speed.

CO2 Laser Cutting Machine: CO2 laser cutting machines generate a CO2 laser beam using a gas mixture, which is then focused onto the workpiece. The laser beam’s energy melts and vaporizes the material for cutting, and this process is also computer-controlled.

Fiber vs CO2 Laser Cutter - Cutting Materials

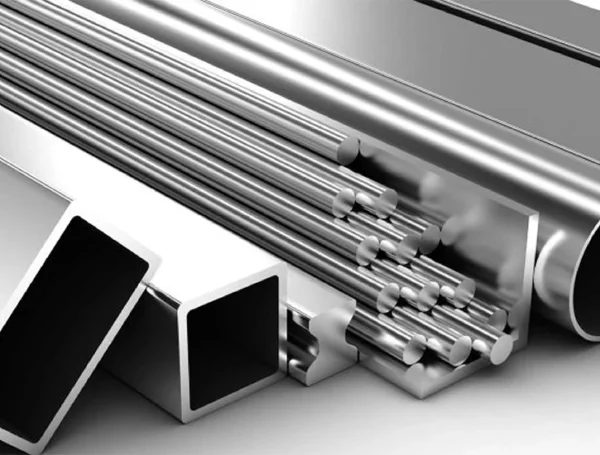

Fiber Laser Cutting Machine: Fiber laser cutting machines are primarily suitable for metal materials. With a wavelength typically around 1μm, they are particularly effective for cutting metals such as stainless steel, carbon steel, galvanized steel, copper, and aluminum. Metals have a high absorption rate for this wavelength, allowing rapid energy absorption and cutting.

CO2 Laser Cutting Machine: CO2 laser cutting machines are mainly used for non-metallic materials. With a wavelength typically at 10.6μm, they are better suited for non-metal materials like wood, acrylic, PP, and organic glass. These materials have a higher absorption rate for this wavelength, making them easier to process.

Fiber vs CO2 Laser Cutter - Cutting Speed

Fiber Laser Cutting Machine: Fiber laser cutting machines generally offer higher cutting speeds, especially when cutting metal materials. Their high energy density and shorter beam wavelength allow for rapid melting and cutting of metal materials, making them competitive in high-speed cutting in production environments.

CO2 Laser Cutting Machine: CO2 laser cutting machines typically have slower cutting speeds, especially when cutting metal materials. Although they are effective in cutting non-metallic materials, their longer wavelength requires more energy for cutting metals, resulting in slower operation.

Fiber vs CO2 Laser Cutter - Production Costs

Initial Investment Costs:

- Fiber Laser Cutting Machine: Fiber laser cutting machines generally have higher initial investment costs due to the advanced laser source, fiber transmission system, and high-precision optical components.

- CO2 Laser Cutting Machine: In contrast, CO2 laser cutting machines typically have lower initial investment costs because the laser source and optical systems are relatively mature and cost-effective.

Operating Costs:

- Fiber Laser Cutting Machine: Fiber laser cutting machines are more cost-effective to operate. Their long-lasting laser source and high energy efficiency reduce energy costs, especially when cutting metal at high speeds.

- CO2 Laser Cutting Machine: CO2 laser cutting machines may have relatively higher operating costs. They require gas mixtures for laser generation, leading to increased gas and energy costs. Additionally, due to the longer wavelength, more energy is required for cutting metal, resulting in higher energy consumption.

Maintenance Costs:

- Fiber Laser Cutting Machine: Fiber laser cutting machines typically require less maintenance. The long lifespan of the fiber laser source and stable optical paths contribute to lower maintenance costs, mainly involving periodic replacement of the fiber laser source and maintenance of optical components.

- CO2 Laser Cutting Machine: CO2 laser cutting machines often require more frequent maintenance. They need regular replacement of gas mixtures, cleaning, and adjustment of optical elements, leading to higher maintenance costs and time.

Fiber vs CO2 Laser Cutter - Environmental Aspects

Fiber Laser Cutting Machine: Fiber laser cutting machines are generally more environmentally friendly. They do not produce harmful gas emissions during operation, as their laser source and transmission system do not require gas mixtures. Additionally, they typically do not generate harmful radiation.

CO2 Laser Cutting Machine: CO2 laser cutting machines may produce waste gas emissions during operation because they use gas mixtures to generate the laser. Some of these gases can be harmful to the environment and need proper treatment. Furthermore, CO2 laser cutting machines can produce laser radiation, requiring additional safety measures to protect operators.

Fiber vs CO2 Laser Cutter - Safety Considerations

Fiber Laser Cutting Machine: Fiber laser cutting machines are generally safer in terms of laser radiation. Their shorter wavelength results in lower laser radiation risk, and operators need to follow standard safety procedures, such as wearing appropriate protective eyewear.

CO2 Laser Cutting Machine: CO2 laser cutting machines require more attention to safety. Their longer wavelength can pose a greater risk of laser radiation to human health. When operating a CO2 laser cutting machine, additional safety measures are essential, such as restricting laser radiation exposure, using protective equipment, and ensuring that the work area complies with safety standards.

Conclusion

Fiber laser cutting machines and CO2 laser cutting machines each have unique advantages and application areas. Fiber laser cutting machines excel in cutting metal and provide high-speed, high-precision cutting, while CO2 laser cutting machines find widespread use in cutting non-metallic materials, especially organics and thicker materials.

The choice of the right cutting machine should be based on specific requirements and materials, considering investment costs, operating costs, maintenance needs, and environmental and safety factors. In practical applications, combining both types of machines may be a viable solution to meet diverse material and cutting requirements.

Ultimately, understanding the working principles and characteristics of these two types of cutting machines will help decision-makers in the manufacturing industry make informed choices.