Laser Welding

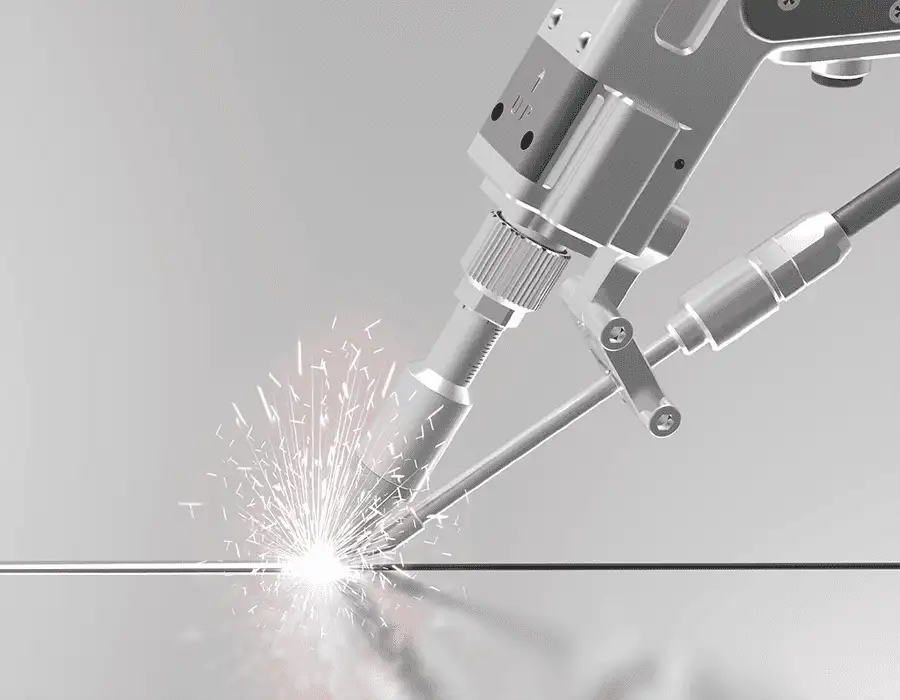

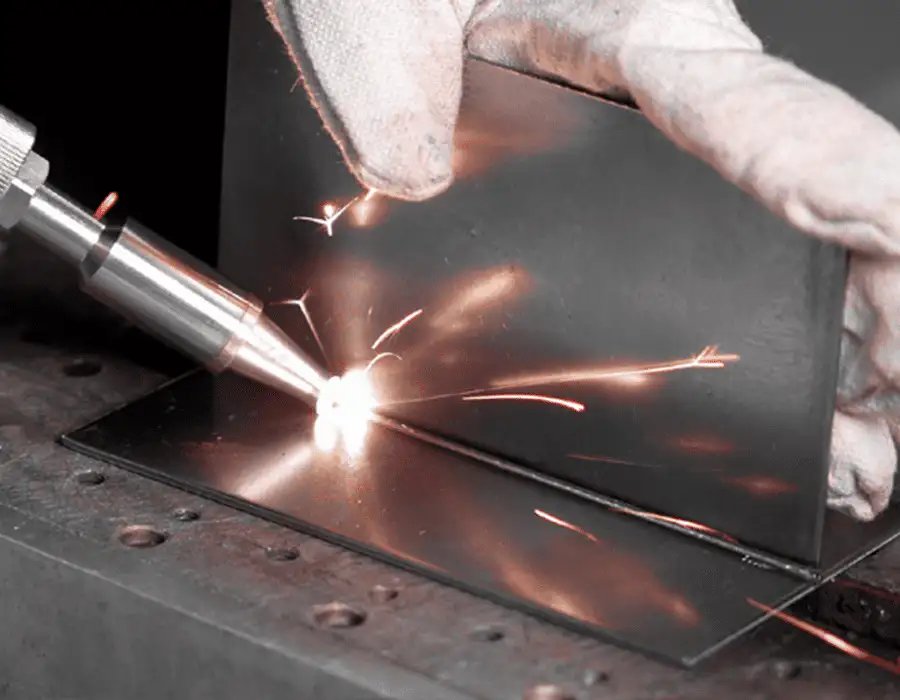

Laser welding is a high-precision joining process that utilizes a focused laser beam to fuse two or more materials together. The process involves directing the laser beam at the target area, where the intense heat generated by the laser causes the materials to melt and then solidify, forming a strong and durable bond.

Key advantages of laser welding include its ability to create precise, narrow welds with minimal heat-affected zones, resulting in minimal distortion and high weld quality. Additionally, laser welding is suitable for a wide range of materials, including metals and plastics. It offers high welding speeds and can be automated for efficiency.

- High precision

- Non-contact method

- Fast Welding speeds

- Suitability for a variety of materials

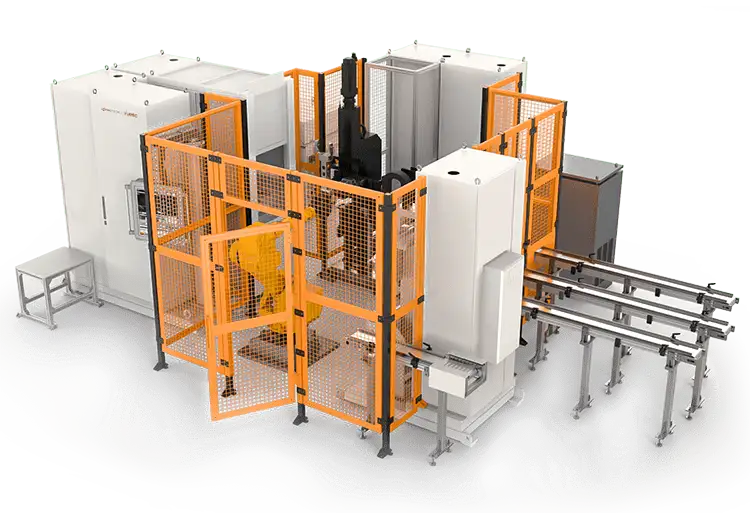

- Automation

- Cleanliness

- Reduced Energy Consumption

- Automotive Industry

- Aerospace Industry

- Electronics Manufacturing

- Medical Device Manufacturing

- Energy Sector

- Jewelry and Watchmaking

- Tool and Die Making

- Telecommunications

- Consumer Electronics

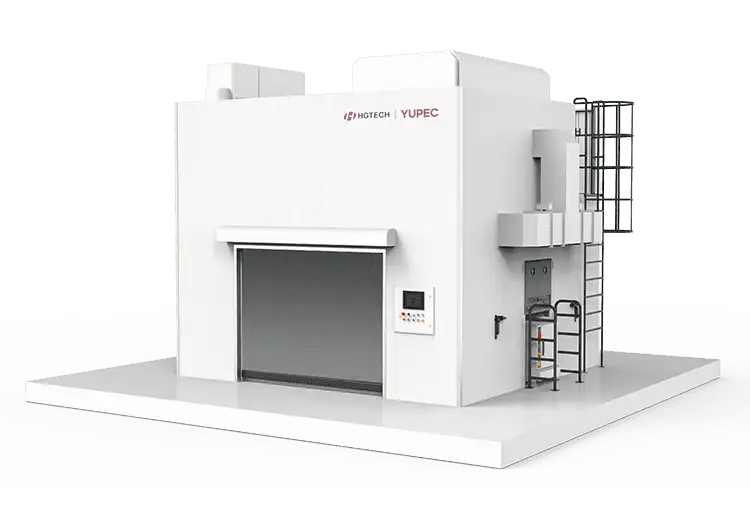

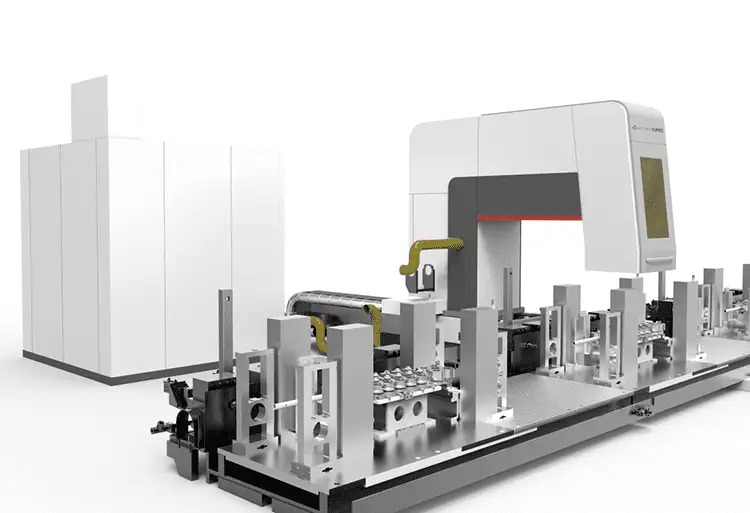

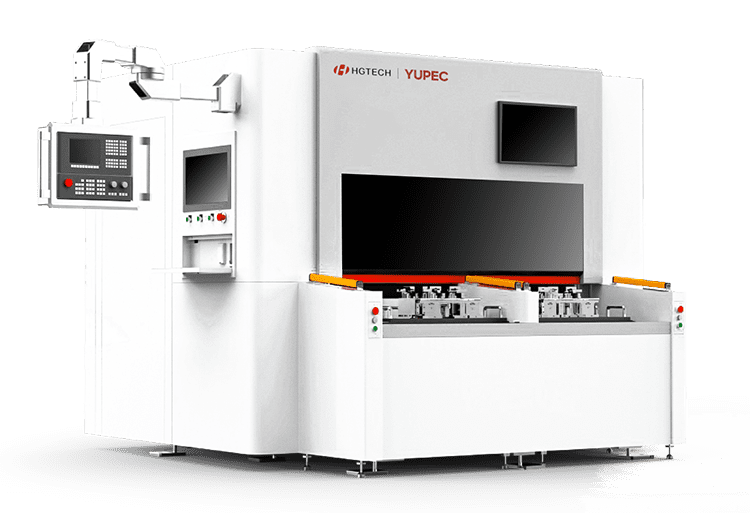

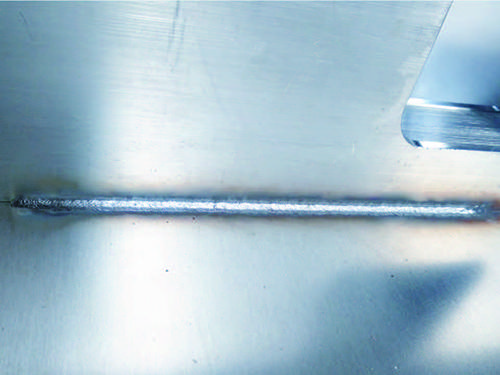

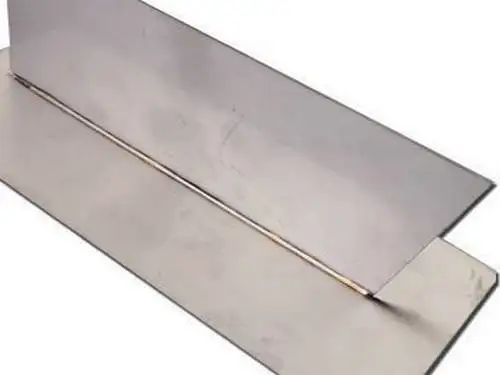

Sample Display

Contact Us

Send us a message

Don’t hesitate to ask, we usually reply in 24 hours or less!

Contact Information

Yupec Laser Germany GmbH

Itterpark 2, 40724 Hilden, Germany

- +49 2103 9674 492 / +49 2103 9676 682

Company Details

Yupec Laser Germany GmbH

Amtsgericht Jena, HRB 519333

Ust-Id~Nr. DE3552294798