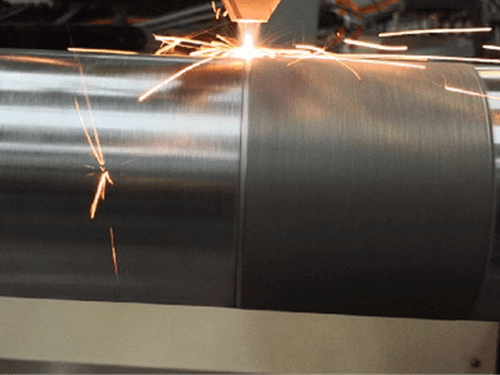

Laser Cladding

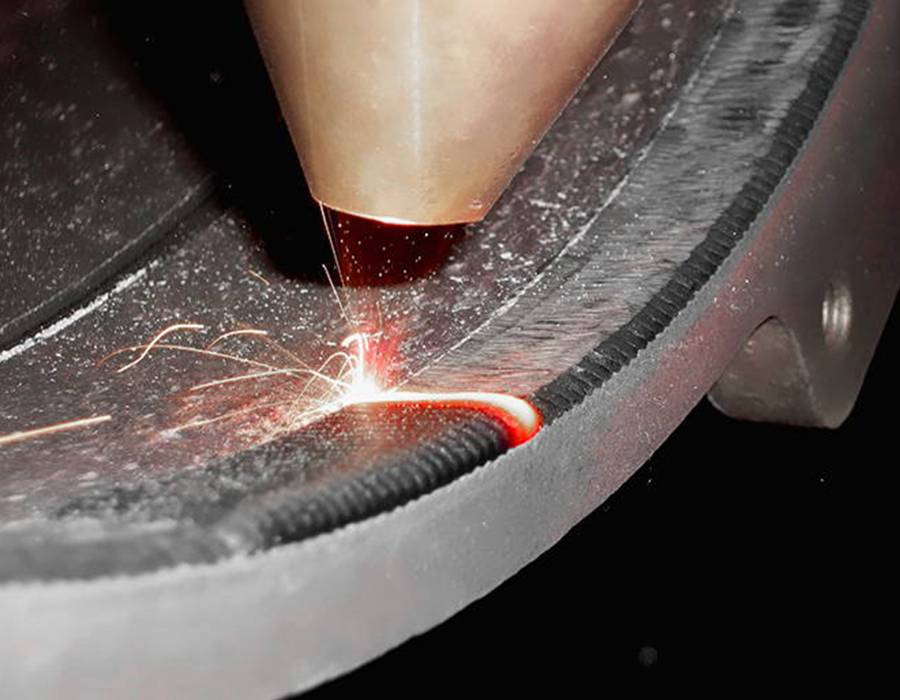

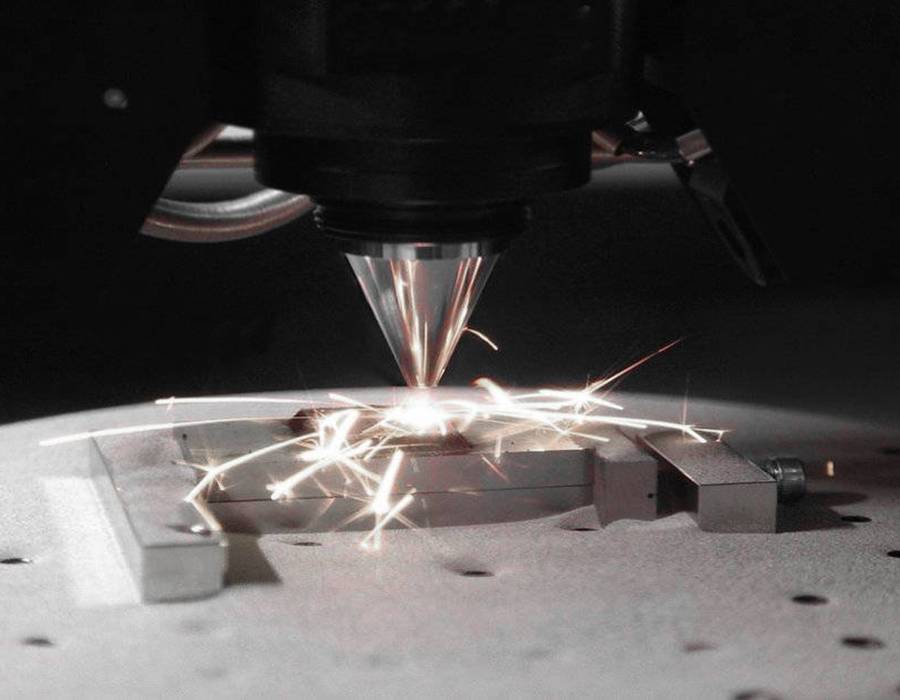

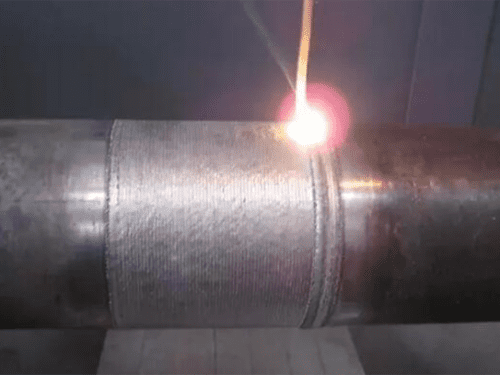

Laser cladding is a precision manufacturing process that involves depositing a layer of material, typically a metal or alloy, onto the surface of a substrate using a high-energy laser beam. Laser cladding selectively adds material to specific areas of a workpiece, allowing for precise and controlled modification of the surface.

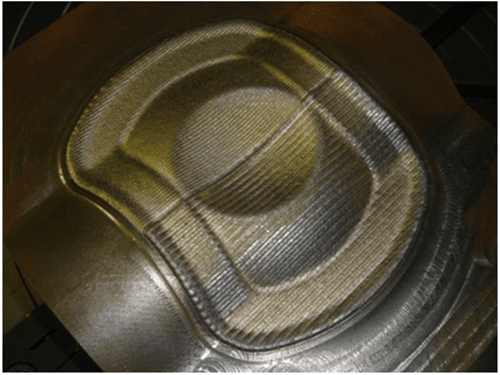

It supports a wide range of materials, including metals, ceramics, and composites, making it adaptable to various applications. Laser cladding allows for customization of material composition, enabling tailored solutions for specific performance requirements.

Laser cladding is utilized in industries such as aerospace, automotive, oil and gas, and tooling, among others, for applications ranging from wear-resistant coatings to part refurbishment.

- High Precision

- Layered Additive Process

- Materials Versatility

- Complex Geometry

- Rapid Prototyping and Production

- Reduced Material Waste

- Heat Control

- Aerospace

- Healthcare and Medical

- Automotive

- Dental and Orthodontics

- Jewelry

- Tooling and Mold Making

- Consumer Electronics

- Education and Research

- Architecture and Design

- Art and Sculpture

- Energy Sector

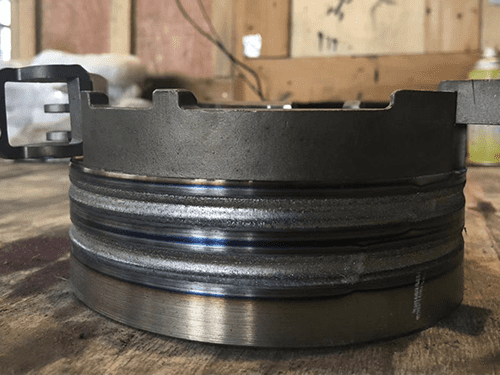

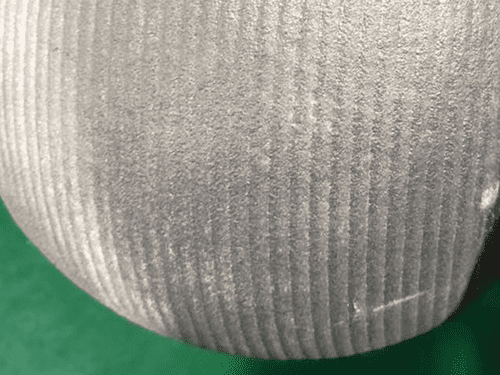

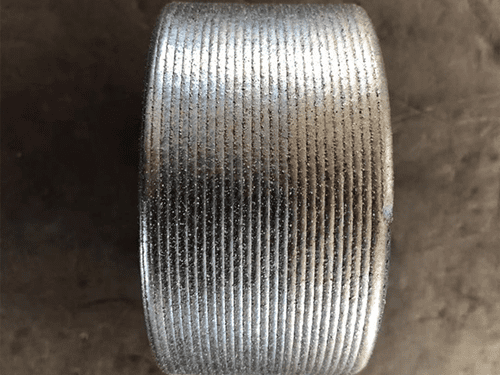

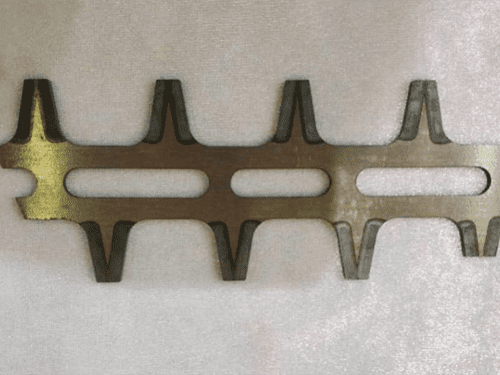

Sample Display

Contact Us

Send us a message

Don’t hesitate to ask, we usually reply in 24 hours or less!

Contact Information

Yupec Laser Germany GmbH

Itterpark 2, 40724 Hilden, Germany

- +49 2103 9674 492 / +49 2103 9676 682

Company Details

Yupec Laser Germany GmbH

Amtsgericht Jena, HRB 519333

Ust-Id~Nr. DE3552294798