Table of Contents

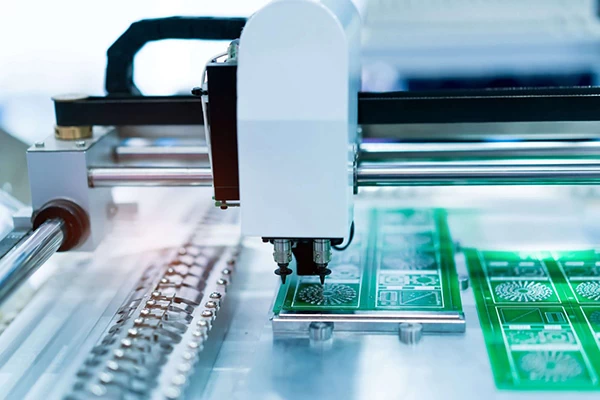

With the rapid development of technology, laser cutting machines have become crucial production tools in various fields. Particularly in the Printed Circuit Board (PCB) industry, the precise, efficient, and versatile characteristics of laser cutting machines have led to their increasingly widespread application. This article will delve into the specific applications of laser cutting machines in the PCB industry.

Why PCB Cutting is Necessary?

The cutting of Printed Circuit Boards (PCBs) involves dividing large boards into smaller ones or cutting an entire circuit board into different sections. This step is a critical process in PCB manufacturing, and several reasons explain why PCB cutting is necessary:

Versatility

A large PCB may contain multiple independent circuits. By cutting the PCB, it can be segmented into smaller pieces, each performing a different function. This allows a single PCB design to be applied to various products.

Space Saving

PCB manufacturing often involves the use of large substrates. Cutting a large PCB into multiple smaller PCBs helps save space, especially in small devices or electronic products.

Cost Reduction

Larger PCBs may be more expensive as they require more materials and production time. Cutting the PCB reduces waste and makes it easier to handle on the production line, ultimately reducing manufacturing costs.

Better Maintenance and Repair

When a PCB is cut into smaller sections, maintenance and repair become easier. If one circuit module is damaged, only the affected small section needs replacement, avoiding the need to replace the entire PCB.

Improved Production Efficiency

In most PCB manufacturing processes, multiple PCBs are typically produced at once and then separated through cutting. This improves production efficiency as multiple boards can be processed simultaneously.

Adaptation to Different Design Requirements

PCB cutting allows manufacturers to adapt to different design requirements. By flexibly configuring the layout of PCBs, manufacturers can meet the needs of different products and specifications.

In summary, PCB cutting allows for a more flexible and cost-effective use of circuit boards, making them adaptable to various applications and design requirements.

Advantages of Laser Cutting PCBs

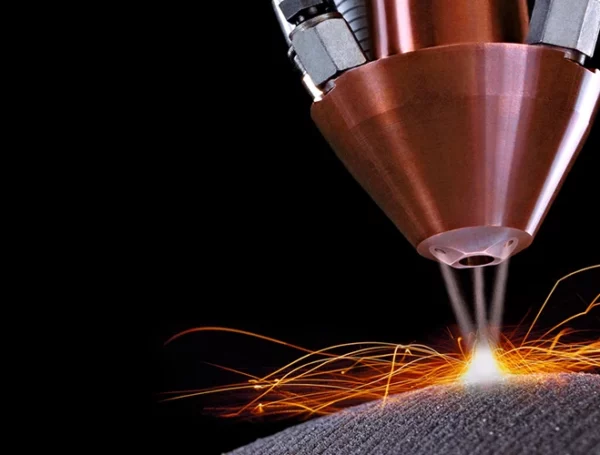

Traditional methods for processing PCBs, including milling, routing, and drilling, have drawbacks such as dust, burrs, and stress, significantly impacting small or component-loaded PCBs. These challenges cannot meet the requirements of new applications. Laser technology applied to PCB cutting provides a new technological direction for PCB processing.

Laser cutting machines demonstrate several significant advantages in cutting PCBs:

High Precision

Laser cutting machines can achieve very high precision, allowing for positioning and cutting at the millimeter or even micrometer level. This is crucial for the manufacturing of PCBs with tiny components and fine traces.

Non-Contact Cutting

Laser cutting is a non-contact cutting method that does not require physical contact with the PCB surface. This helps prevent mechanical damage, especially when dealing with complex circuits and sensitive components.

High-Speed Processing

The laser cutting process is typically very fast, enabling rapid PCB cutting. This contributes to improved production efficiency, especially in large-scale production.

Flexibility

Laser cutting machines can adapt to various shapes and sizes of PCBs without the need for tool changes or additional adjustments. This flexibility allows them to meet different design requirements.

Fine Processing

Laser cutting can achieve very fine cuts, suitable for high-density PCBs and the processing of small-sized components. This is crucial for the increasingly compact designs of modern electronic products.

No Tool Changes Required

Unlike traditional mechanical cutting, laser cutting does not require the use of tools, avoiding issues related to tool wear and replacement, reducing downtime on the production line.

Zero Waste

Since laser cutting is precisely controlled by a laser beam, it minimizes waste production, improving material utilization.

Applicable to Complex Profiles

Laser cutting machines can easily handle complex profiles and intricate structures, which is beneficial in the manufacturing of high-end electronic devices.

In summary, PCB cutting allows for a more flexible and cost-effective use of circuit boards, making them adaptable to various applications and design requirements.

Application of Laser Cutting Machines in PCB Manufacturing

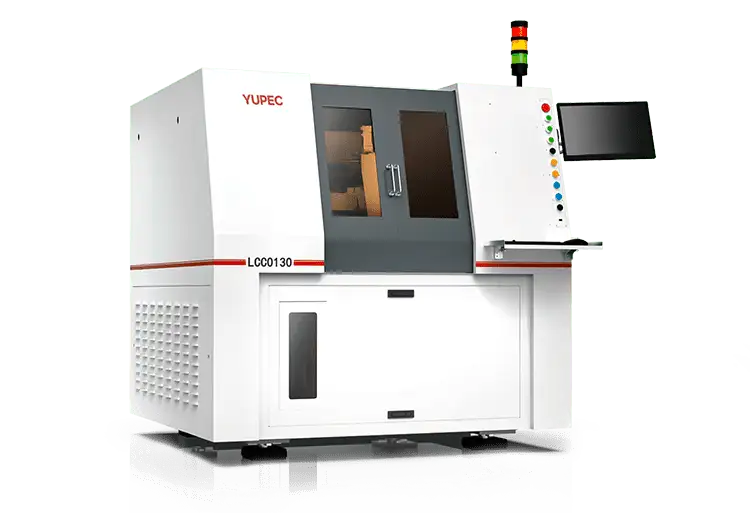

With the rapid development of intelligent electronics, PCBs as one of the core components of electronic products have become subject to stricter manufacturing requirements. The application of laser cutting equipment in the PCB industry is increasingly becoming an essential tool to enhance processing precision and adapt to new designs. The following discusses specific applications in response to this trend:

PCB Laser Cutting and Depaneling

Laser cutting machines are commonly used for the precise cutting and depaneling of PCBs. As electronic devices become smaller, and circuit board complexity increases, laser cutting machines can achieve high-precision cutting, ensuring the dimensional accuracy and quality of PCBs. This is crucial for meeting the design requirements of small electronic devices.

PCB Drilling

With the increasing number of PCB layers, traditional mechanical drilling methods may no longer suffice. Laser cutting machines are widely used in high-precision drilling operations. Their non-contact nature and highly precise control allow laser cutting machines to perform accurate drilling of tiny holes on PCBs, suitable for manufacturing high-density circuit boards.

HDI Board Drilling

HDI (High-Density Interconnect) boards typically contain small and dense holes for connecting different circuit layers. Laser cutting machines demonstrate unique advantages in drilling holes on HDI boards, ensuring high-precision processing of tiny holes and reliable high-density interconnections.

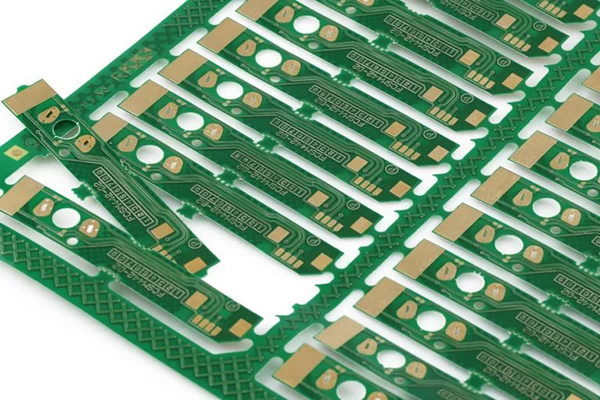

FPC Outline Cutting and Drilling

In the manufacturing of Flexible Printed Circuit (FPC) boards, laser cutting machines are commonly used for the outline cutting and drilling of FPC boards. FPCs often require higher flexibility and intricate designs, and the non-contact and highly precise processing of laser cutting machines make them an ideal choice for handling FPCs.

FPC Cover Film Cutting

FPCs are often covered with thin films, and laser cutting machines can be used for precisely cutting these films. This ensures that sensitive components on the circuit board are not damaged. Maintaining the structural integrity and electrical performance of FPCs is crucial, making laser cutting an essential process.

These application examples clearly demonstrate the multifunctionality and adaptability of laser cutting machines in the PCB industry. Their high precision and non-contact characteristics make them ideal for meeting the high demands of modern electronic industries in terms of PCB design and manufacturing.

Impact of Laser Cutting Machines on PCB Manufacturing

Improved Production Efficiency and Reduced Manufacturing Costs:

The high-speed processing and efficiency of laser cutting machines make the PCB manufacturing process faster. By processing multiple PCB boards at once and separating them through cutting, manufacturers can complete production tasks in a shorter time, improving overall production efficiency. Compared to traditional cutting methods, laser cutting’s tool-free operation and efficient processing reduce manufacturing costs, enhancing the competitiveness of electronic products.

Enhanced Precision and Quality in PCB Manufacturing:

Laser cutting machines, with their high-precision cutting, improve the overall precision and quality of PCB manufacturing. The fine cutting ensures the precise layout of small components and tiny traces on the PCB, enhancing the performance and reliability of the circuit board. This is particularly significant for manufacturers requiring high-quality electronic products.

Potential for Sustainable Manufacturing:

Laser cutting technology’s zero-waste characteristic and highly flexible processing offer potential opportunities for sustainable manufacturing. The precise cutting process reduces waste generation, allowing manufacturers to utilize materials more efficiently and reduce environmental impact. This aligns with the modern manufacturing industry’s requirements for sustainability and environmental friendliness, making laser cutting technology more attractive in PCB manufacturing.

In conclusion, the widespread application of laser cutting machines and their many advantages have driven the electronic manufacturing industry towards more precise, efficient, and sustainable directions. This technology has not only changed the PCB manufacturing process but also provided more advanced and reliable solutions for the design and production of modern electronic products.

Conclusion

As a crucial technology in the PCB manufacturing field, laser cutting machines have brought significant changes to the electronic manufacturing industry with their advantages of high precision, efficiency, and flexibility. As technology continues to advance, the application of laser cutting machines in the PCB industry will continue to evolve, providing more reliable and advanced solutions for the design and manufacturing of electronic products.