Table of Contents

Oil stains are common in our daily lives, accumulating on various surfaces like engines, train components, molds, and other equipment due to extended usage. Failure to regularly clean these oil stains can negatively impact the performance and lifespan of these components. Laser cleaning machines offer several technological advantages in the cleaning process, including intelligent control, precise positioning, non-destructive treatment of the substrate, and user-friendliness. They also provide economic and social benefits such as environmental friendliness, low operation and maintenance costs, improved working conditions, and reduced labor requirements. In the realm of oil stain cleaning, laser cleaning is poised to replace traditional cleaning methods and become the best choice for future oil stain removal.

Traditional Oil Stain Cleaning Methods

Oil stains mainly consist of substances like grease, lubricants, and motor oil that adhere to metal surfaces. Traditional cleaning methods use cleaning agents to dissolve and disperse these oil stains, which require significant water usage during the cleaning process, causing environmental pollution. Additionally, cleaning agents can pose health hazards to humans. Another conventional method involves mechanical friction to remove oil stains by applying mechanical force to the surface of the object to be cleaned, which can easily damage the substrate and is time-consuming.

Traditional cleaning methods have multiple disadvantages and do not align with today’s strict environmental standards. Laser cleaning, as a product of industrial development in the modern era, breaks through the technological barriers of traditional cleaning and represents an eco-friendly cleaning method. It overcomes the shortcomings of traditional cleaning, such as the need for cleaning agents, complex cleaning procedures, and long cleaning cycles, ensuring nontoxic and environmentally friendly cleaning of oil stains on the surface of objects.

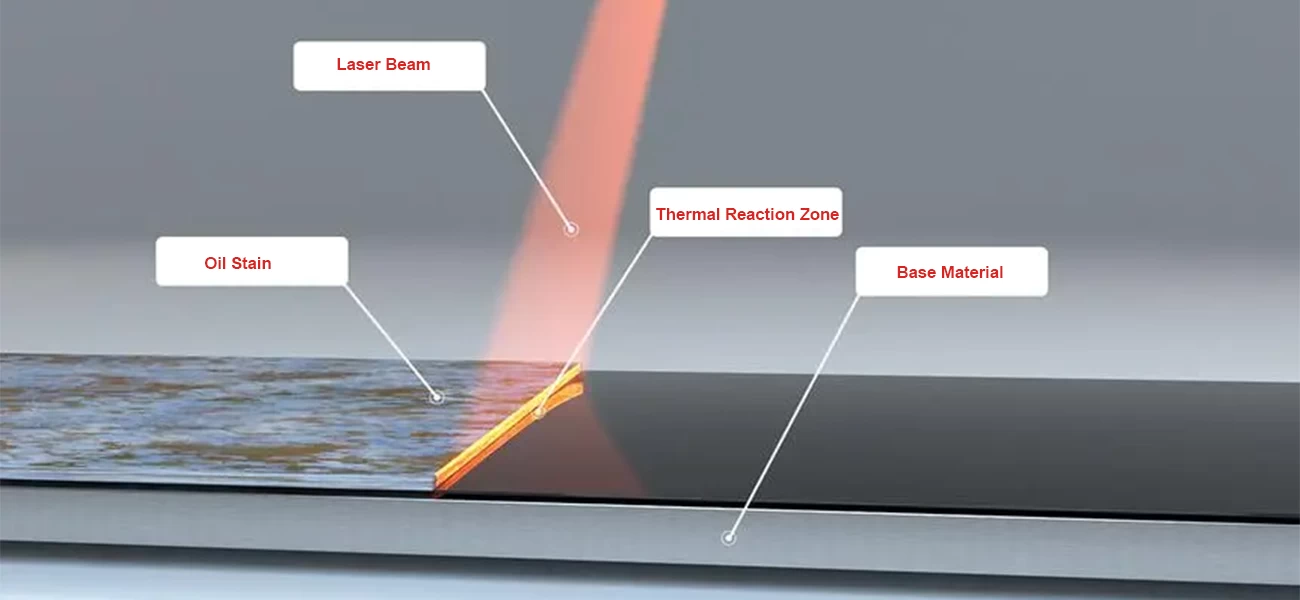

Principle of Laser Cleaning of Oil Stains

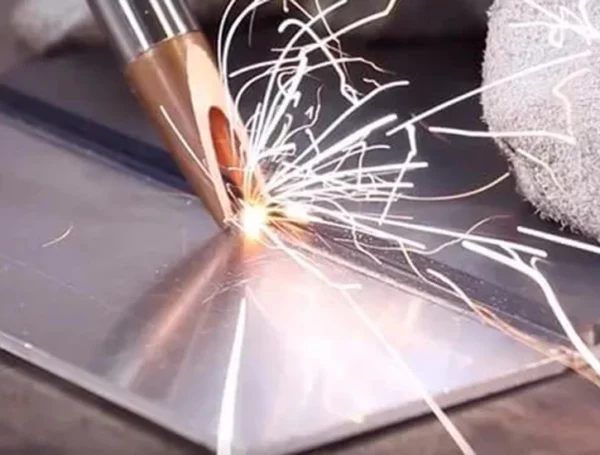

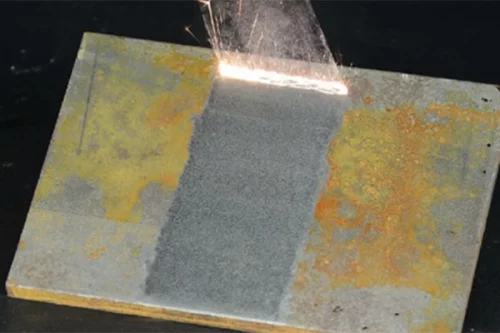

By using high-frequency, high-energy laser pulses to irradiate the surface of the workpiece, the contaminant layer can instantly absorb the focused laser energy, causing the surface oil to evaporate or peel off instantly, thus efficiently removing surface oil contamination. Since the duration of laser pulse action is very short, it will not damage the substrate as long as the appropriate parameters are used.

Advantages of Laser Cleaning for Oil Stains

Laser cleaning machines, which utilize laser technology for cleaning, provide efficient removal of oil stains in industry:

- Laser cleaning machines deliver highly effective cleaning. They employ the high energy of laser beams to rapidly disintegrate and remove dirt from the surface of oil stains. This method not only efficiently removes oil stains but also reduces damage to the surface of the workpiece. Compared to traditional cleaning methods, laser cleaning machines provide a cleaner oil stain removal process and enhance cleaning effectiveness.

- Laser cleaning machines offer non-contact cleaning capabilities. Using laser beams for cleaning eliminates the need for direct contact with the workpiece’s surface, preventing damage and contamination caused by contact. This non-contact cleaning method safeguards the quality and cleanliness of the workpiece surface while reducing friction and wear caused by contact, extending the service life of the workpiece.

- Laser cleaning machines offer precise control. They can precisely control parameters such as laser beam power, focusing, and scanning speed to fine-tune the cleaning process. This precise control capability enables laser cleaning machines to tailor cleaning to the characteristics and requirements of different workpieces, enhancing cleaning effectiveness and efficiency.

- Laser cleaning machines possess environmental and energy efficiency. They do not require the use of chemical solvents or cleaning agents, reducing environmental pollution and harm. Furthermore, laser cleaning machines only consume electrical energy during the cleaning process, reducing energy consumption compared to traditional cleaning methods and demonstrating high energy efficiency.

- Laser cleaning machines exhibit automation and intelligence. Through integration with computers and robotic equipment, laser cleaning machines can achieve automated control and intelligent operation during the cleaning process. This automation and intelligence enable laser cleaning machines to meet the demands of efficient and large-scale production, improving work efficiency and product quality.

In summary, the application of laser cleaning in removing oil stains is essential for improving work efficiency, protecting the environment, enhancing product quality, and ensuring equipment longevity. It is a green cleaning method that does not rely on chemical cleaning agents, conserves energy, and reduces waste. However, selecting the appropriate laser system, parameters, and technology is essential to ensure cleaning effectiveness and safety. As laser technology continues to advance, laser cleaning will continue to play a significant role in various fields.

Applications of Laser Cleaning for Oil Stains

Laser cleaning finds wide-ranging applications in the removal of oil stains, particularly in the industrial and manufacturing sectors. Here’s a detailed discussion of the applications of laser cleaning for oil stains:

- Automotive Manufacturing: During the production of automobiles, engine components and the surfaces of vehicle bodies are often affected by oil and dirt. Laser cleaning effectively removes these oil stains, ensuring the cleanliness of automotive components and the quality of assembly and painting work. Furthermore, laser cleaning in the automotive manufacturing industry reduces the use of harmful waste and chemicals, contributing to environmentally friendly production.

- Aircraft Maintenance and Repair: The aviation industry demands strict cleanliness and quality for aircraft components. Laser cleaning is employed to eliminate oil stains, coatings, and contaminants from the surfaces of aircraft. This extends the aircraft’s lifespan, enhances performance, and ensures safety during flight.

- Mechanical Equipment Maintenance: Maintaining clean surfaces for mechanical equipment is vital for their proper operation. Laser cleaning is used to remove oil stains, coatings, and dust from the surfaces of mechanical equipment, reducing friction, extending component life, and improving equipment efficiency.

- Food Processing Equipment: The food processing industry requires a highly sanitary environment and equipment to ensure food quality and safety. Laser cleaning is applied to remove grease and residues from food processing equipment surfaces, preventing bacterial growth and guaranteeing the hygiene and safety of food products.

- Electronics Manufacturing: In the electronics manufacturing process, precise cleaning of circuit boards and electronic components is crucial. Laser cleaning effectively removes oil stains and other contaminants, ensuring the reliability and performance of electronic components.

- Building and Cultural Heritage Preservation: In architecture and cultural heritage preservation, laser cleaning is employed to remove oil stains, dirt, and old coatings from building surfaces. This helps restore the original appearance of structures and protects cultural heritage from contamination and degradation.

In Conclusion

The application of laser cleaning in the removal of oil stains is pivotal for improving efficiency, preserving the environment, enhancing product quality, and extending equipment life. It offers a green cleaning solution without the need for chemical cleaning agents, and it conserves energy while reducing waste production. Nevertheless, choosing the right laser system, parameters, and technology is essential to ensure effective and safe cleaning. As laser technology continues to advance, laser cleaning will continue to play a significant role in various industries.