Construction Navale

Shipbuilding characteristics and technical difficulties

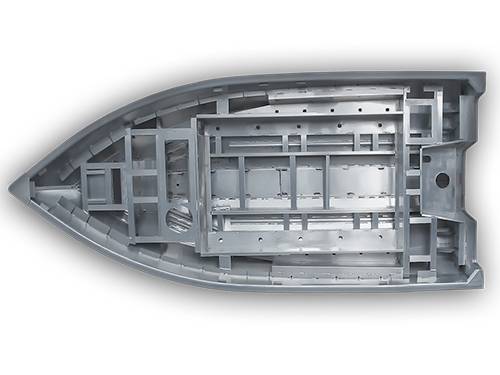

From the perspective of consumers and end users, shipbuilding is a highly specialized and technology-intensive field. In recent years, customer or consumer demand for ships has increasingly tended to be multifunctional, environmentally friendly and intelligent. With the growth of global trade, the demand for ships is also growing steadily. Consumers now pay more attention to the safety, comfort and energy efficiency of ships. In addition, with the global trend towards green shipping and reduction of carbon emissions, customers are increasingly looking for ships with more environmentally friendly materials and technologies. In addition, as technology advances and intelligence develops, customer demand for smart ships and automated equipment is gradually increasing. To meet these demands, ship manufacturers need to continuously innovate and upgrade their products and technologies.

From a shipbuilder’s point of view, meeting consumer expectations and demands is a daunting task. With the development of the market, the shipbuilding industry is facing technical difficulties and challenges in many aspects. First of all, how to realize environmental protection and energy efficiency of ships is an important issue now and in the future. Manufacturers need to develop new technologies and materials to reduce carbon emissions and environmental pollution from ships. Secondly, with the development of intelligent and automated technologies, ship manufacturers need to continuously develop and upgrade their technologies to meet customer demand for intelligent ships and automated equipment. In addition, the shipbuilding industry is faced with high costs and technological complexity. In order to ensure the safety and performance of ships, manufacturers need to invest a lot of money and resources to develop and test new technologies and solutions. Further, the shipbuilding industry needs to continuously research and develop new design and manufacturing technologies to improve ship productivity and reduce costs. These are the technical difficulties and challenges that the shipbuilding industry needs to face and solve now and in the future.

Application of YUPEC's products in the shipbuilding industry and customer benefits

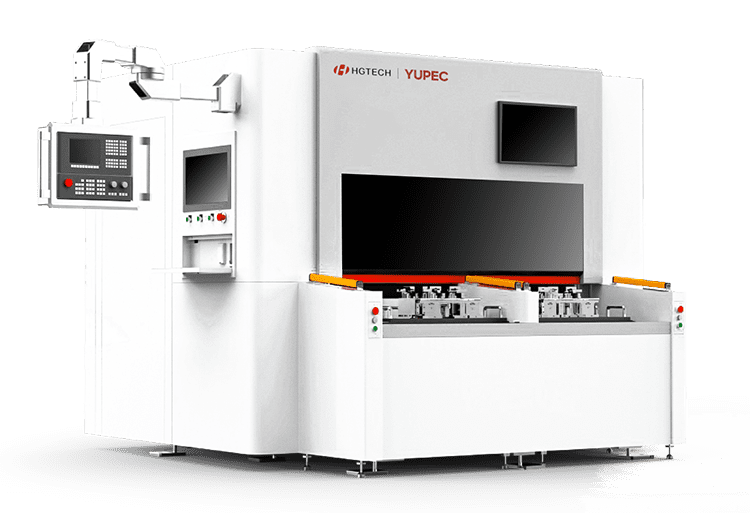

Système de Découpe Laser Flexible pour Matériaux Non Métalliques

In the fabrication of hulls and ship interiors, this system enables high-precision cutting of non-metallic materials. For example, it ensures accuracy and consistency when creating interior insulation and composite components.

The system can also be used for fine decoration and design of the ship’s interior, including customized instrument panels and unique upholstery, which will greatly enhance the ship’s aesthetics and comfort.

With its ultrasonic welding capability, this system provides more flexibility and accuracy for structural strengthening and repair of marine fittings, thus improving the efficiency and quality of maintenance.

Deploying the Non-Metal Flexible Laser Cutting System notably benefits the shipbuilding industry. It guarantees manufacturing accuracy and lowers costs by reducing material waste.

Moreover, it amplifies the aesthetic and comfort level of the ship’s interiors, promising better market acceptance and sales prospects. The system also offers a potent solution for structural enhancement and maintenance, cutting down long-term costs and time. Additionally, its intuitive HMI interface simplifies operation, decreasing staff training time and boosting efficiency, positioning companies advantageously in a competitive market.

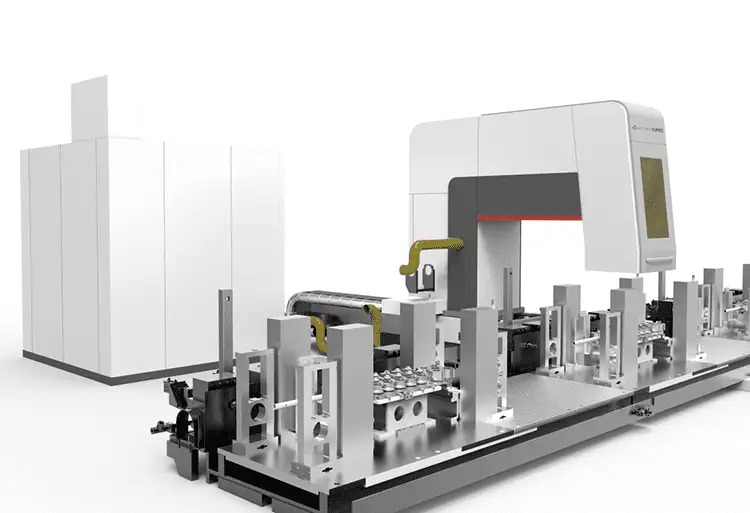

Système de Découpe et de Soudage Laser Flexible avec Robot

In the shipbuilding industry, this system can be used for cutting and welding large hull structural components. Its highly flexible robot performs complex cutting and welding tasks with precision, thus ensuring the structural stability and durability of the ship.

This system can also be used for precision processing of ship interiors. For example, when making high-level interior decorations for ships, precise cutting and welding of various materials can be realized, thus enhancing the quality and aesthetics of the overall decorations.

The system can also be used for the manufacture and maintenance of a wide range of ship accessories and components, including key components such as anchors and propulsion systems. It enables efficient and high-quality production, thus ensuring the safety and performance of ships.

The Robot Flexible Laser Cutting and Welding System revolutionizes the shipbuilding industry by merging cutting and welding functions into a single, swiftly switchable unit, slashing equipment change time and operational costs while boosting productivity.

With high-precision, highly flexible robots, it conducts complex tasks, enhancing product quality and workflow efficiency. This versatile system not only fosters innovation, elevating market competitiveness and profitability but also increases customer satisfaction through improved product quality, thus expanding market share.

Système de Connexion par Soudage Laser pour Conduites de Ligne

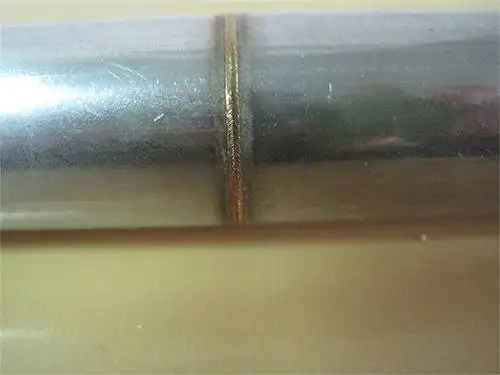

In the shipbuilding industry, this system can be used to weld part of the hull’s steel structure at the joints. Utilizing its high speed and high precision, it enables fast and high quality welding of hull structures, ensuring the strength and stability of the hull.

It can be used to fabricate complex piping systems commonly found in the shipbuilding industry, including exhaust pipes and cooling systems. Its high-strength welded connections ensure a stable and reliable piping system that avoids leaks and failures.

This system can also be used to manufacture various fittings and structural components for ships, such as crash beams, brackets, etc., for greater safety and durability.

The Line Pipe Laser Welding Connection System bolsters the shipbuilding industry by enhancing welding strength and efficiency, vital in crafting safety features like crash beams. It surpasses TIG welding speeds, eliminates slag issues common in high-frequency welding, and reduces post-processing, cutting costs and accelerating production.

Its high accuracy and repeatability ensure consistent output, minimizing waste and hastening market entry. Integrated with advanced rolling lines, it supports seamless welds and meets diverse manufacturing needs. Furthermore, it lessens the heat-affected zone and offers a pleasing finish, reducing time and costs while improving product quality, solidifying a leadership position in the competitive shipbuilding market.

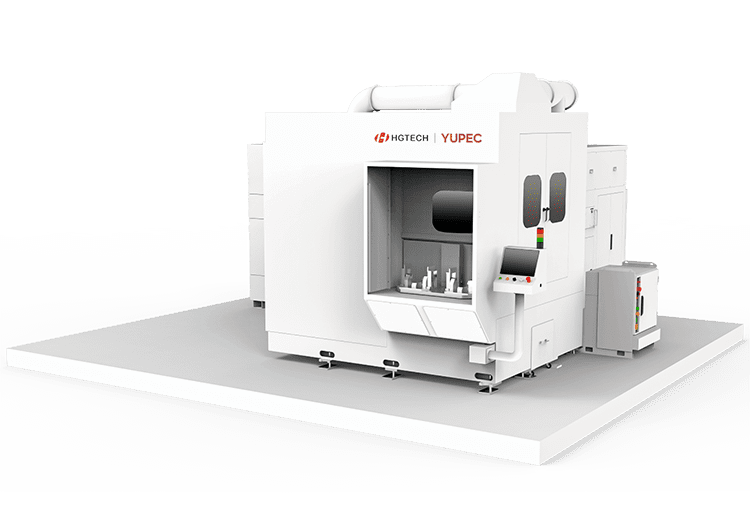

Système de Soudage Laser Machine-Outil CNC

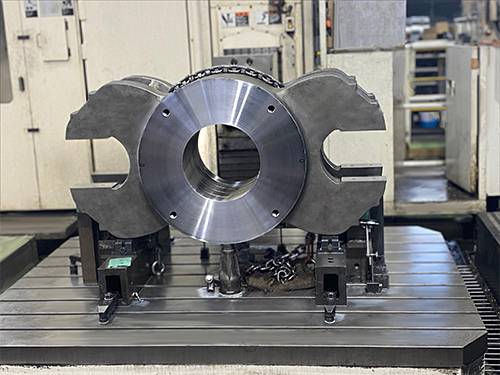

Hull and Structure Welding in the Shipbuilding Industry: Used for welding large structural parts of a ship’s hull such as sides, decks and hulls. The system enables high-precision and high-efficiency welding, ensuring a strong and durable hull structure.

Welding of Marine Pipes and Fittings: In the welding of marine pipes and related fittings, fast, high-quality laser welding can be realized, which significantly improves production efficiency and product quality.

Welding of Marine Equipment and Mechanical Components: Used for welding of equipment and mechanical components (such as engines, pumps and valves) on board ships to achieve efficient and precise welding and ensure safe and reliable operation of the equipment.

The JKB series CNC laser welding station is a boon for mass production in the shipbuilding industry. It ensures superior weld quality and structural safety of ships with high precision and repeatability. It notably boosts productivity, cutting down lead times and costs, enhancing market competitiveness.

Its integrated controls save space and facilitate a streamlined shop layout, while its fast travel speed and adaptable table dimensions respond flexibly to various welding demands, reducing production time and costs. Ultimately, adopting this system promises increased market share, profits, and sustainable growth, by meeting diverse machining needs efficiently and maintaining high product quality.

Série Cube - Haute Puissance Fusion Profonde par Soudage Laser

Deep welding of hull structural parts: The system is suitable for high-quality deep welding of hull structural parts, which ensures a high depth-to-width ratio, high structural strength and long fatigue life of the weld seam.

Welding of Complex Marine Equipment Components: In the welding of complex marine equipment components (such as marine pressure vessels and piping systems), efficient and precise deep fusion welding can be realized to ensure product quality and safety.

Welding of Marine Steel Structures: Used for welding of marine steel structures (e.g., hull frames and brackets) to realize high-quality and high-efficiency deep-melt welding and improve the structural strength and safety of products.

The Cube series of high-power laser deep welding systems significantly enhance shipbuilders’ productivity and product quality through advanced features that ensure smooth production flow and consistency, reducing errors and costs.

Its customizable features adapt to various operational needs, minimizing scrap. Equipped with a modern CCD vision system and Precitec YW52 welding heads, it guarantees precise and uniform welding operations, bolstering market competitiveness and profitability, fostering sustained business growth.

Système de Nettoyage Intelligent Collaboratif Multi-Robot

Marine Engine Parts Cleaning: The system can be used to clean complex internal cavity structure parts during the manufacturing process of marine engines to ensure compliance with the ISO 16232 cleanliness standard, thus improving the reliability and life of marine engines.

Hull Structure Cleaning: It can be used to clean various parts of the hull structure, such as steel plates and weld seams, to remove oil and impurities and ensure the quality of welding and painting.

Marine Pipeline and Valve Cleaning: Suitable for high pressure cleaning and deburring of marine pipelines and valves to ensure the cleanliness and safety of the pipeline system.

Using a 6-axis robot and CCD camera, this system offers precise cleaning meeting ISO 16232 standards, with energy-efficient and easily maintained screw vacuum pump technology.

Its high-pressure deburring cleaning function, adaptable to varied cleaning needs, delivers fast and precise results. The multi-step robotic conveyor facilitates flexible cleaning solutions for complex parts, reducing scrap rates and maintenance costs, thereby lowering overall expenses.

Consequently, shipbuilders can attain superior cleanliness and quality, enhanced productivity, competitiveness, and minimized operational costs and environmental impact.